يناير . 30, 2025 01:10 Back to list

diagram of steam boiler

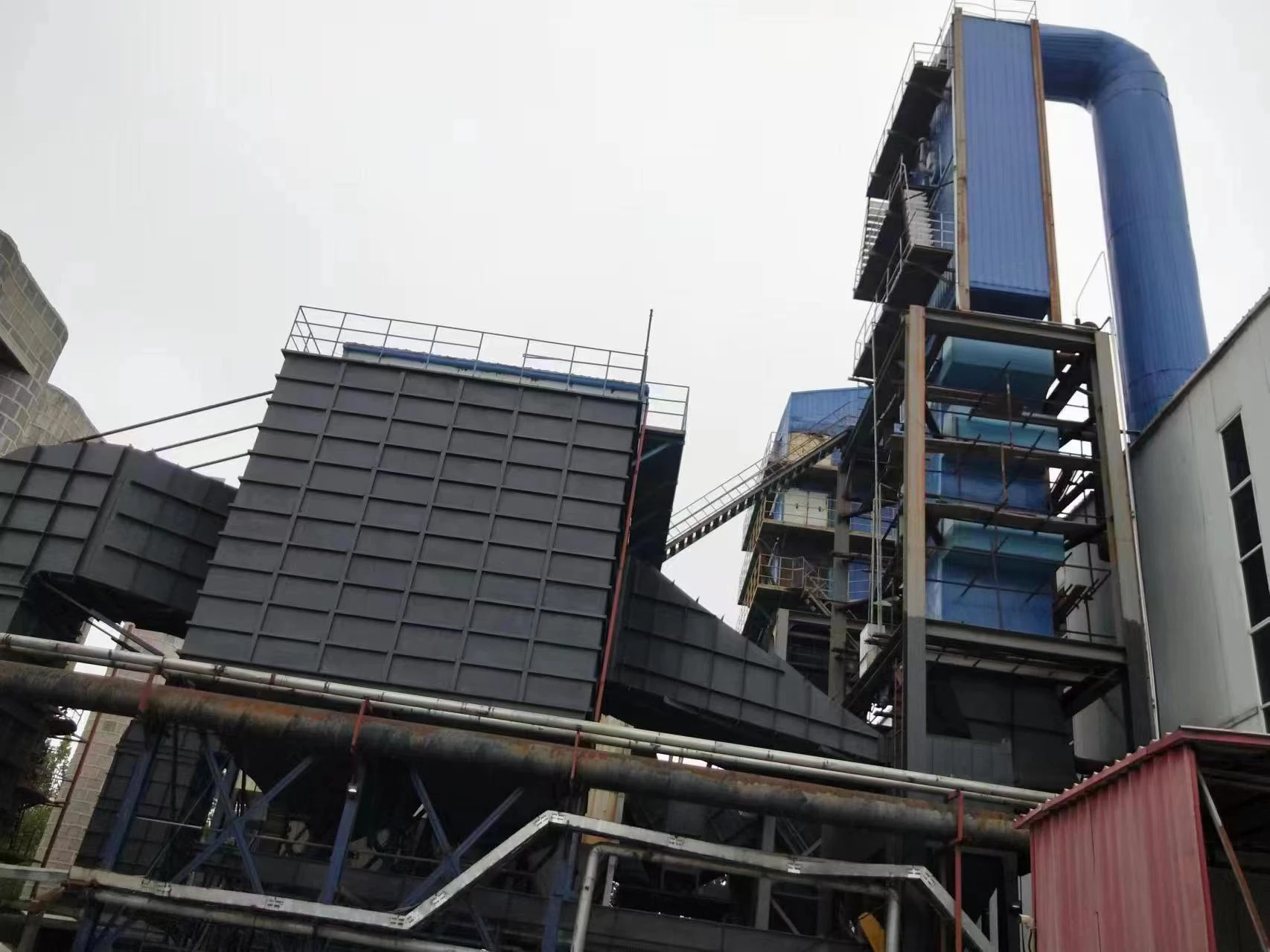

Understanding the intricate workings of a steam boiler is crucial for those in the industrial sector. Steam boilers play a vital role in power generation, heating, and numerous industrial processes. This article offers a comprehensive insight into steam boilers, focusing on the diagrammatic representation and its significance in effective operational management.

A clear depiction is required for safety components such as safety valves, depicted prominently to indicate their critical roles in pressure release and system protection. Accidents prevention procedures can be better understood through these diagrammatic representations, underscoring the importance of maintenance and regular checks. Professionals trust diagrams to stimulate comprehensive preventive maintenance plans. These diagrams guide placement and connections of water treatment systems including blowdown tanks and chemical dosing systems which mitigate issues like scale formation and corrosion. Consequently, boiler efficiency and lifespan are enhanced significantly. Emphasizing automation, modern steam boiler diagrams incorporate control panels. These diagrams detail sensor connections and programmable logic controllers that oversee and automate operational efficiency and safety. Automation, as illustrated, is pivotal in contemporary practice, allowing for remote monitoring and intelligent data analysis in operational workflow. Diagrams and technical illustrations serve as authoritative resources for training and operational procedure refinement. They provide clarity in design, ensuring that both seasoned operators and newcomers have a reliable visual aid. Modern diagrams are enriched with digital twins, allowing simulation of real-time scenarios enhancing training modules. Emerging trends in steam boiler technology are increasingly focused on sustainability. Contemporary diagrams often include integrations with renewable energy sources, conversion to alternative fuels, and emissions reduction technologies. An emphasis on these features can provide users with a more environment-friendly operational perspective. Ultimately, a steam boiler diagram is more than just a technical drawing; it is a tool of immense professional value that blends engineering precision with practical application. For those seeking expertise and reliability in steam boiler operation, a well-interpreted diagram offers the authoritative understanding needed to drive efficiency and safety in industrial settings. Understanding and employing the detailed information these diagrams provide ensures a comprehensive approach toward energy management and sustainability.

A clear depiction is required for safety components such as safety valves, depicted prominently to indicate their critical roles in pressure release and system protection. Accidents prevention procedures can be better understood through these diagrammatic representations, underscoring the importance of maintenance and regular checks. Professionals trust diagrams to stimulate comprehensive preventive maintenance plans. These diagrams guide placement and connections of water treatment systems including blowdown tanks and chemical dosing systems which mitigate issues like scale formation and corrosion. Consequently, boiler efficiency and lifespan are enhanced significantly. Emphasizing automation, modern steam boiler diagrams incorporate control panels. These diagrams detail sensor connections and programmable logic controllers that oversee and automate operational efficiency and safety. Automation, as illustrated, is pivotal in contemporary practice, allowing for remote monitoring and intelligent data analysis in operational workflow. Diagrams and technical illustrations serve as authoritative resources for training and operational procedure refinement. They provide clarity in design, ensuring that both seasoned operators and newcomers have a reliable visual aid. Modern diagrams are enriched with digital twins, allowing simulation of real-time scenarios enhancing training modules. Emerging trends in steam boiler technology are increasingly focused on sustainability. Contemporary diagrams often include integrations with renewable energy sources, conversion to alternative fuels, and emissions reduction technologies. An emphasis on these features can provide users with a more environment-friendly operational perspective. Ultimately, a steam boiler diagram is more than just a technical drawing; it is a tool of immense professional value that blends engineering precision with practical application. For those seeking expertise and reliability in steam boiler operation, a well-interpreted diagram offers the authoritative understanding needed to drive efficiency and safety in industrial settings. Understanding and employing the detailed information these diagrams provide ensures a comprehensive approach toward energy management and sustainability.

Share

Next:

Latest News

-

Best Steam Boiler Design PDF Free Design Calculation & Diagram Downloads

NewsJun.10,2025

-

Hot Boiler Water Heater Efficient Heating Solutions for Home & Commercial Use

NewsJun.10,2025

-

Steam Boiler Safety Devices High-Quality Protection Valves

NewsJun.10,2025

-

Ultimate Steam Boiler Checklist for Safety & Efficiency

NewsJun.10,2025

-

Optimal Hot Water Boiler Temperature Setting Guide

NewsJun.10,2025

-

Effective Hot Water Boiler Chemical Treatment Protect & Maintain

NewsJun.09,2025

Related PRODUCTS

Copyright © 2025 HEBEI HONGZE BOILER MANUFACTURING CO., LTD. All Rights Reserved. Sitemap | Privacy Policy