अक्टूबर . 11, 2024 16:29 Back to list

Understanding the Boiling Points of Thermal Oils for Efficient Heat Transfer Applications

Understanding the Boiling Point of Thermal Oil Significance and Applications

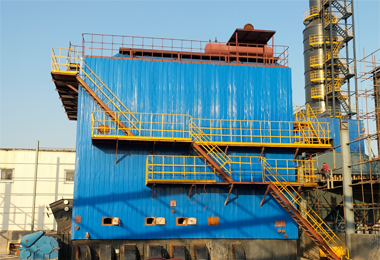

Thermal oils, also known as heat transfer fluids, are critical components in various industrial processes, especially those requiring precise temperature management. Their primary purpose is to transfer heat from one location to another efficiently. One of the most important characteristics of thermal oils is their boiling point, which significantly influences their performance and applicability in different settings.

What is Thermal Oil?

Thermal oils are organic compounds designed to operate at high temperatures while maintaining thermal stability. Unlike water, which has a boiling point of 100°C (212°F) at atmospheric pressure, thermal oils can withstand much higher temperatures, typically ranging from 200°C to 400°C (392°F to 752°F), and some advanced formulations can even reach up to 600°C (1112°F) or higher. This characteristic makes them suitable for applications in industries like chemical processing, food production, and power generation.

Importance of Boiling Point

The boiling point of thermal oil is crucial for several reasons

1. Thermal Stability A high boiling point indicates that the thermal oil can withstand elevated temperatures without vaporizing. This stability is essential in processes where prolonged heat exposure is required, such as in reactors and distillation columns.

2. Heat Transfer Efficiency The efficiency of heat transfer is often closely related to the boiling point of the thermal oil. Oils with higher boiling points can carry more thermal energy, ensuring that processes operate smoothly without overheating or underheating.

3. Reduced Risk of Degradation Thermal oils are prone to oxidation and thermal degradation over time. A higher boiling point generally correlates with better resistance to these processes, thereby prolonging the life of the thermal fluid and reducing maintenance costs.

4. Safety Considerations Operating below the boiling point of the thermal oil minimizes the risk of accidents related to pressure build-up in the system, which can occur if the oil begins to vaporize. This is particularly relevant in industries where safety is paramount, such as petrochemicals.

thermal oil boiling point

Applications of Thermal Oil

Thermal oils are widely used across various sectors because of their advantageous properties. Some prominent applications include

- Chemical Processing In the production of chemicals, precise temperature control is essential. Thermal oils provide consistent heating for reactors and heat exchangers, facilitating optimal reaction conditions.

- Food Production In processes such as frying, roasting, and pasteurization, thermal oils are employed to maintain the desired temperature, ensuring that food products meet safety and quality standards.

- Power Generation Concentrated solar power (CSP) plants utilize thermal oils to transfer heat from solar collectors to a steam generator. This heat is then converted into electricity, demonstrating the utility of thermal oils in renewable energy applications.

- Plastics and Rubber Manufacturing The compounding and molding processes in plastics and rubber production require sustained high temperatures. Thermal oils help maintain these temperatures, ensuring the quality and consistency of the final products.

Selecting the Right Thermal Oil

When choosing a thermal oil for a particular application, it is essential to consider its boiling point along with other factors such as thermal conductivity, viscosity, and chemical compatibility. Manufacturers often provide detailed specifications that outline the operational parameters of their products. The choice of thermal oil can have a considerable impact on operational efficiency, safety, and cost-effectiveness.

Conclusion

The boiling point of thermal oil is more than just a number; it is a decisive factor that influences thermal stability, heat transfer efficiency, and overall system safety. As industries continue to evolve and demand more efficient heating solutions, understanding the properties and applications of thermal oils becomes increasingly important. Whether in chemical processing, food production, or power generation, thermal oils play a pivotal role in ensuring that processes run smoothly and efficiently at high temperatures. As technology advances, further innovations in thermal oil formulations are likely to enhance their effectiveness and expand their applications in various fields.

-

Oil Fired Hot Water Boilers Sale - High Efficiency & Affordable

NewsJul.31,2025

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

Related PRODUCTS