ធ្នូ . 26, 2024 16:52 Back to list

6 ton boiler

Understanding 6% Ton Boilers Efficiency and Application in Modern Industries

In today’s industrial landscape, efficient energy usage is paramount for both economic and environmental reasons. Among the various thermal systems employed, boilers play a crucial role in generating steam or hot water for heating, power generation, and various other processes. A specific type that merits attention is the six-ton boiler, commonly denoted as a 6% ton boiler. This article will explore what a 6-ton boiler is, its efficiency, operational mechanics, and its applications in modern industries.

What is a 6 Ton Boiler?

A 6-ton boiler refers to a steam or hot water boiler that has the capacity to produce six tons of steam per hour. This measurement is a standard metric in the boiler industry, correlating to the thermal energy output required for various industrial processes. Boilers are categorized by their efficiency, type (fire-tube, water-tube), and application. The 6-ton capacity is particularly significant for industries that require substantial heating and steam generation, such as food processing, textile manufacturing, chemical production, and power generation.

Efficiency of 6 Ton Boilers

Efficiency is one of the most critical factors when evaluating a boiler for industrial use. A well-designed 6-ton boiler can achieve remarkable efficiency ratings, often exceeding 85% under optimal conditions. Efficiency affects fuel consumption, operational costs, and overall performance. Modern technologies, such as condensing economizers and advanced combustion control systems, enhance the efficiency of these boilers by minimizing heat loss and maximizing energy extraction from the fuel.

Moreover, the emissions from a 6-ton boiler can also be reduced through advanced burners and emission control technologies, promoting a cleaner operation that aligns with global standards for environmental sustainability. As industries continue to face stricter regulations regarding emissions, the shift towards more efficient boilers like the 6-ton variant becomes integral not only for compliance but also for promoting a greener future.

Key Components and Operation

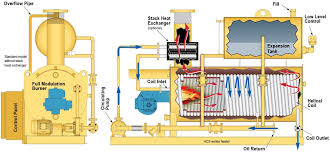

6 ton boiler

A typical 6-ton boiler comprises several critical components the combustion chamber, heat exchanger, water feed system, and control systems. The combustion chamber facilitates the burning of fuel (natural gas, diesel, biomass, or coal), producing the necessary heat to convert water into steam. The heat exchanger then transfers this heat to the water, significantly increasing the temperature and pressure to generate steam.

The boiler system operates under a closed-loop, where the steam produced is utilized in various industrial processes, such as powering turbines or heating systems. After delivering its energy, the steam condenses back into water and is recirculated, ensuring efficient use of resources.

Applications in Industries

The versatility of a 6-ton boiler makes it suitable for a wide range of applications in various sectors. In the food processing industry, for instance, these boilers are essential for cooking, sterilization, and cleaning purposes. Textile manufacturers utilize steam for dyeing and finishing processes, while chemical plants rely on them for heating and maintaining reaction temperatures.

Additionally, in power generation, a 6-ton boiler can serve as a pivotal component in combined heat and power (CHP) systems, where both electricity and thermal energy are produced simultaneously, enhancing overall energy efficiency.

Conclusion

In conclusion, a 6-ton boiler represents a vital asset in the pursuit of industrial efficiency and sustainability. Its ability to deliver high levels of thermal energy while maintaining operational efficiency and lower emissions positions it as an ideal solution for various industries. As technology advances further, the design and capabilities of 6-ton boilers will continue to evolve, leading to enhanced performance and even greater contributions to energy efficiency and environmental stewardship. Investing in such technology not only meets current industrial demands but also paves the way for a sustainable future.

-

High-Efficiency On-Off Steam Boiler for Reliable Heating Solutions Compare with Off Boiler Water Heaters & Steam Generators

NewsJun.24,2025

-

Best Steam Boiler Design PDF Free Design Calculation & Diagram Downloads

NewsJun.10,2025

-

Hot Boiler Water Heater Efficient Heating Solutions for Home & Commercial Use

NewsJun.10,2025

-

Steam Boiler Safety Devices High-Quality Protection Valves

NewsJun.10,2025

-

Ultimate Steam Boiler Checklist for Safety & Efficiency

NewsJun.10,2025

-

Optimal Hot Water Boiler Temperature Setting Guide

NewsJun.10,2025

Related PRODUCTS