8월 . 15, 2024 13:29 Back to list

Selecting the Right Steam Boiler for Optimal Efficiency and Performance in Industrial Applications

Selection of Steam Boilers Key Considerations and Factors

When it comes to industrial applications, steam boilers play an essential role in generating steam for various processes, including heating, sterilization, and power generation. The selection of an appropriate steam boiler can significantly impact efficiency, cost-effectiveness, and operational reliability. This article explores the key considerations and factors that should be evaluated when selecting a steam boiler for any industrial application.

1. Type of Boiler

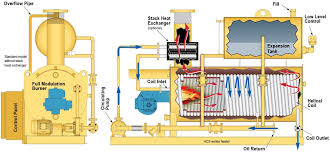

The first step in the selection process is determining the type of boiler that best suits the needs of the facility. There are primarily two types of steam boilers fire-tube boilers and water-tube boilers. Fire-tube boilers contain hot gases that pass through tubes surrounded by water; they are generally more suitable for lower pressure and steam output applications. On the other hand, water-tube boilers allow water to flow through tubes heated by combustion gases. These are better suited for high-pressure applications and provide higher steam generation capacity.

2. Capacity and Output Requirements

Next, it is essential to assess the facility's steam requirements. The boiler's capacity, measured in British Thermal Units (BTUs), must meet the output demand. Understanding peak demand times and potential for expansion in planning can help in selecting a boiler that fits current needs while accommodating future growth. It is vital not to under-specify the boiler, as undersized units can lead to inadequate performance, while oversized units can result in inefficiency and higher operational costs.

3. Fuel Type

The choice of fuel is a crucial factor in selecting a steam boiler. Common fuel types include natural gas, propane, oil, coal, and biomass. The availability and cost of these fuels in the local area should be considered alongside environmental regulations that may apply. For instance, natural gas is often preferred due to its clean-burning properties and lower emissions compared to coal. However, if a facility has access to inexpensive biomass or waste products, a biomass boiler might be a more sustainable choice.

selection of steam boiler

4. Efficiency

Boiler efficiency is another critical aspect to consider. The efficiency of a boiler indicates how well it converts fuel into usable steam. It is typically expressed as a percentage, with higher percentages denoting better performance. Factors affecting efficiency include the boiler design, the control systems in use, and the method of combustion. High-efficiency boilers can significantly reduce fuel consumption and operational costs, making them a more cost-effective long-term investment despite potentially higher upfront costs.

5. Emission Standards and Regulations

Compliance with emission standards is paramount for industrial facilities. Different regions have varying regulations pertaining to air quality and emissions. Before selecting a steam boiler, it is necessary to ensure it meets the local environmental regulations regarding NOx, SOx, and particulate emissions. Choosing a boiler designed to optimize combustion and minimize emissions can avoid potential legal issues and promote sustainable operations.

6. Maintenance and Serviceability

Lastly, the ease of maintenance and serviceability of the steam boiler is critical. A boiler with high uptime and reliability helps ensure consistent operation. Consideration should be given to the availability of replacement parts, accessibility for repairs, and the manufacturer's reputation for service. Implementing a robust maintenance schedule can further enhance the longevity and efficiency of the boiler system.

Conclusion

In conclusion, the selection of a steam boiler involves careful consideration of multiple factors, including the type of boiler, capacity, fuel type, efficiency, regulatory requirements, and maintenance needs. By thoroughly evaluating these aspects, industries can make informed decisions that lead to enhanced operational efficiency and reduced costs. A well-chosen boiler system not only meets immediate steam generation needs but also supports sustainable and reliable operation well into the future.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS