Nov . 19, 2024 03:29 Back to list

Understanding the Operational Mechanics of Steam Boilers in Industrial Applications

The Working Principle of a Steam Boiler

Steam boilers are essential components in various industrial processes, providing heat energy through the generation of steam

. These boilers operate based on fundamental principles of thermodynamics and fluid mechanics, converting water into steam through the application of heat.At the heart of a steam boiler's operation is the heat exchanger, where heat is transferred from a fuel source to water. Typically, this process starts when water is fed into the boiler from a feed tank. The water is then heated by burning fuel—such as natural gas, coal, or oil—in a combustion chamber. This combustion process generates hot gases, which flow through fire tubes or are contained within the boiler's shell, thus transferring heat to the water.

As the temperature of the water rises, it eventually reaches its boiling point, transforming into steam. This steam accumulates in a designated space within the boiler—known as the steam drum—where it is stored until needed. The pressure and temperature of the steam can be controlled by regulating the fuel feed and the flow of water into the boiler, ensuring optimal efficiency and safety during operation.

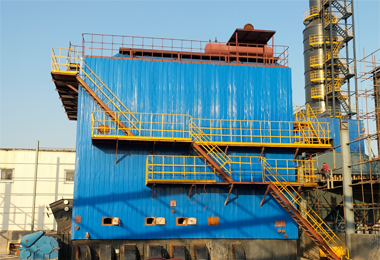

steam boiler working principle

Moreover, steam boilers can be classified into two main types fire-tube boilers and water-tube boilers. In fire-tube boilers, hot gases pass through tubes submerged in water, whereas, in water-tube boilers, water flows through tubes surrounded by hot gases. Each design has its advantages regarding efficiency, pressure capacity, and response time.

The steam produced in these boilers is then utilized for various applications, such as driving turbines for electricity generation, providing heat for industrial processes, or supplying steam for heating buildings. The flexibility and efficiency of steam boilers make them an integral part of modern energy and industrial systems.

To ensure safety and durability, steam boilers are equipped with numerous safety devices, including pressure relief valves, water level controls, and alarms. Regular maintenance and inspections are also crucial to prevent malfunctions and prolong the lifespan of the boiler.

In conclusion, the working principle of a steam boiler encompasses the conversion of water into steam through heat transfer from combustion processes. Its design and operation are pivotal in ensuring the reliable provision of steam for various industrial and commercial applications, underscoring the importance of this technology in today’s energy landscape.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS