10 сар . 31, 2024 19:41 Back to list

Maximizing Efficiency in Steam Boiler Design and Operation Techniques

The Most Efficient Steam Boiler An Overview

In today’s industrial landscape, efficiency is paramount, especially when it comes to energy consumption. Steam boilers play a critical role in various industries, including power generation, manufacturing, and even food processing. Given their substantial demand for energy, finding the most efficient steam boiler is essential for reducing operational costs and minimizing environmental impact.

Understanding Steam Boiler Efficiency

Steam boiler efficiency refers to the ability of the boiler to convert fuel into steam energy while minimizing losses through combustion, heat transfer, and exhaust. A highly efficient boiler can significantly lower fuel consumption, which directly translates to reduced greenhouse gas emissions and greater sustainability.

The efficiency of a steam boiler is typically expressed as a percentage, indicating the ratio of useful energy output to energy input. A boiler with an efficiency rating of 90% means that 90% of the energy from the fuel is converted into steam, while 10% is lost in various processes. Modern advancements in technology have resulted in boilers achieving efficiency ratings exceeding 95%.

Types of Efficient Steam Boilers

1. Fire-Tube Boilers These are traditional steam boilers where hot gases pass through tubes surrounded by water. Fire-tube boilers are generally less efficient than water-tube boilers but can be more cost-effective for smaller operations.

2. Water-Tube Boilers In water-tube boilers, water circulates inside the tubes, while hot gases surround them. This design allows for higher pressure and temperatures, leading to improved efficiency. Water-tube boilers are favored in large-scale operations due to their high efficiency and ability to generate steam rapidly.

3. Condensing Boilers These advanced boilers capture and recycle waste heat from flue gases to preheat water entering the boiler. By maximizing heat recovery, condensing boilers can achieve efficiencies of over 95%, making them some of the most efficient options available.

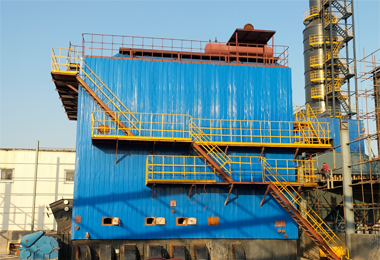

most efficient steam boiler

Factors Influencing Boiler Efficiency

Several factors can affect the efficiency of a steam boiler

- Fuel Quality The type and quality of fuel used can impact efficiency. High-quality, clean fuels lead to better combustion and reduced emissions.

- Operation and Maintenance Regular maintenance and correct operation are crucial for maintaining efficiency. Neglected boilers can suffer from scale buildup, corrosion, or improper combustion, which decrease performance.

- Insulation Proper insulation of pipes and the boiler itself can reduce heat loss, increasing overall efficiency.

- Control Systems Automated control systems can optimize boiler operation by adjusting parameters based on real-time demands, enhancing efficiency.

Conclusion

Investing in the most efficient steam boiler is crucial for organizations aiming to improve both their bottom line and their environmental footprint. With advancements in technology and an increasing focus on sustainability, the market is replete with options that deliver outstanding efficiency. By considering factors such as type, operation, and maintenance, industries can select the best steam boiler to fit their needs and contribute to a more sustainable future. Ultimately, the transition to more efficient steam boilers not only benefits the environment but also proves advantageous economically, paving the way for a greener industrial landscape.

-

How to Maintain a Steam Boiler Expert Tips for Efficiency & Longevity

NewsApr.29,2025

-

Professional Steam Boiler Service AB Expert Maintenance & Repair

NewsApr.29,2025

-

Hot Water Steam Boilers Efficient Heating Solutions & Expert Tips

NewsApr.29,2025

-

Hot Water Boiler Capacity Calculation Guide Efficient Design Tips

NewsApr.28,2025

-

How to Drain a Steam Boiler Step-by-Step Safety Guide

NewsApr.28,2025

-

How to Install a Hot Water Boiler Optimal Pressure & Efficiency Guide

NewsApr.28,2025

Related PRODUCTS