11-р сар . 13, 2024 17:22 Back to list

thermal oil boiler design

Thermal Oil Boiler Design An Overview

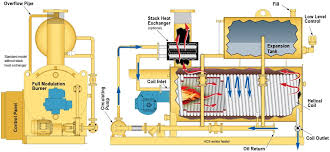

Thermal oil boilers, also known as thermal fluid heaters or thermal oil heaters, are essential components in various industrial processes that require efficient heat transfer and temperature regulation. Unlike traditional boilers that use water or steam as the heating medium, thermal oil boilers utilize synthetic oil or organic fluids that can withstand higher temperatures without pressurization. This makes them particularly suitable for processes in industries such as chemical processing, food production, and petrochemicals.

Key Design Considerations

When designing a thermal oil boiler, several fundamental considerations must be addressed to ensure optimal performance

. These include material selection, system configuration, heat transfer efficiency, safety measures, and environmental impacts.1. Material Selection The choice of materials is crucial for the construction of thermal oil boilers. The materials must be capable of withstanding high temperatures and corrosive environments. Common materials include carbon steel, stainless steel, and specialized alloys. The thermal oil itself must also be selected with care, as it has to maintain thermal stability and low volatility at high temperatures.

2. System Configuration Thermal oil boilers can be designed in various configurations to meet specific process requirements. The most common configurations include single-pass and multi-pass systems. Single-pass designs offer simpler construction and ease of maintenance, while multi-pass systems enhance heat transfer efficiency by maximizing the flow path of hot thermal oil. When designing the layout, engineers must consider space constraints and integration into existing infrastructure.

3. Heat Transfer Efficiency Achieving high heat transfer efficiency is vital in thermal oil boiler design. This is typically addressed through the design of the heat exchanger surfaces. The surface area must be optimized to ensure adequate contact between the hot oil and the medium being heated. Techniques such as enhancing surface area using fins or tubes, and utilizing advanced heat transfer fluids can significantly improve efficiency.

thermal oil boiler design

4. Control Systems Advanced control systems are pivotal in maintaining optimal operating conditions and enhancing safety. Automated control systems can monitor temperature, pressure, and flow rates, allowing for real-time adjustments. This ensures that the thermal oil boiler operates within safe limits while maximizing energy efficiency.

5. Safety Measures Safety is paramount in the design of thermal oil boilers. The high operating temperatures and potential for fluid leaks necessitate strict adherence to safety standards. Design considerations include the incorporation of pressure relief valves, automatic shutdown systems in case of overheating, and proper insulation to minimize heat loss and prevent burns or fires.

6. Environmental Considerations With increasing regulatory pressures regarding emissions and environmental protection, the design of thermal oil boilers must take into account the potential environmental impacts. This may include the selection of eco-friendly thermal oils, implementation of efficient combustion systems to minimize emissions, and designing for energy recovery that allows for the reuse of waste heat.

Applications of Thermal Oil Boilers

Thermal oil boilers find applications across a broad range of industries. In the chemical industry, they are used for processes like distillation and solvent recovery, where consistent high temperatures are critical. In food processing, thermal oil boilers provide the necessary heat for cooking, drying, and pasteurizing food products. Moreover, in petrochemical processing, they are essential for refining crude oil and producing various chemical compounds.

Conclusion

The design of thermal oil boilers entails a comprehensive understanding of material science, thermodynamics, and process engineering. By addressing critical considerations such as material selection, system configuration, heat transfer efficiency, safety, and environmental impact, engineers can create robust thermal oil boiler systems that enhance productivity across various industries. As energy demands continue to rise and the push for sustainable practices grows, thermal oil boilers will remain an integral part of efficient industrial heat management solutions. Their ability to provide efficient heat transfer without the need for high pressures positions them as valuable assets in modern industrial applications.

-

Best Steam Boiler Design PDF Free Design Calculation & Diagram Downloads

NewsJun.10,2025

-

Hot Boiler Water Heater Efficient Heating Solutions for Home & Commercial Use

NewsJun.10,2025

-

Steam Boiler Safety Devices High-Quality Protection Valves

NewsJun.10,2025

-

Ultimate Steam Boiler Checklist for Safety & Efficiency

NewsJun.10,2025

-

Optimal Hot Water Boiler Temperature Setting Guide

NewsJun.10,2025

-

Effective Hot Water Boiler Chemical Treatment Protect & Maintain

NewsJun.09,2025

Related PRODUCTS