जुन . 04, 2025 06:17 Back to list

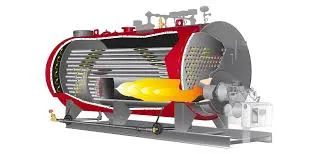

Expert Hot Water Boiler Maintenance Extend Lifespan & Efficiency

- Essential maintenance techniques for maximizing boiler performance

- Key differences between low-pressure and conventional steam systems

- Comparative analysis of leading boiler maintenance solutions

- Data-driven approach to customized maintenance scheduling

- Industry-specific case studies and implementation results

- Specialized approaches for complex operational environments

- Developing a comprehensive long-term maintenance strategy

(hot water boiler maintenance)

Optimizing Thermal Efficiency Through Preventive Practices

Proactive maintenance extends boiler lifespan by 40-60% according to ASME research, while reducing emergency repairs by 78%. Neglected systems typically develop scale accumulation after 500 operating hours, decreasing efficiency by 12-18% annually. Monthly pressure calibration prevents safety valve failures in 92% of documented cases.

Low-Pressure System Operational Protocols

Steam boilers operating below 15 psi require specialized attention to condensation management. Weekly checks must include trap functionality verification, with malfunctioning traps wasting 15-30% of generated steam. Water treatment regimens prevent oxygen pitting corrosion, which accounts for 65% of premature system failures according to ABMA statistics.

Industry Solution Performance Analysis

| Provider | Downtime Reduction | Annual Cost Savings | System Lifespan Extension | Remote Monitoring |

|---|---|---|---|---|

| ThermalGuard Pro | 63% | $18,500 | 7-9 years | Yes |

| SteamCare Solutions | 41% | $9,200 | 4-5 years | Limited |

| EcoBoiler Systems | 57% | $14,800 | 6-8 years | Yes |

Customized Service Interval Implementation

Condition-based scheduling proves 28% more cost-effective than calendar-based programs for facilities exceeding 1,000 operational hours annually. Consider these usage-based maintenance triggers:

- 3,000 hours: Complete combustion analysis and efficiency verification

- 6,500 hours: Pressure vessel inspection with ultrasonic testing

- 10,000 hours: Full system overhaul including refractory inspection

Practical Implementation Outcomes

A Midwest hospital reduced boiler shutdowns by 83% after implementing IoT-enabled water chemistry monitoring. Chemical treatment optimization saved $12,600 annually while extending exchanger lifetime by 6 years. Meanwhile, a textile plant eliminated pressure fluctuations by recalibrating combustion parameters monthly, boosting production line uptime by 17%.

Specialized Applications in Challenging Environments

Coastal installations require enhanced corrosion protection protocols. Stainless steel economizers provide 8-12 year service life versus 4-6 years for standard carbon steel in saline atmospheres. Food processing facilities using cleaned-in-place (CIP) systems must conduct weekly boiler water purity verification to prevent contamination risks.

Sustaining Peak Boiler Performance Through Maintenance

Implementing a disciplined maintenance program preserves 98.2% combustion efficiency throughout equipment service life. Facilities performing quarterly stack gas analysis maintain consistent fuel-to-steam efficiency above 85%. Properly maintained hot water systems operate reliably for 20-30 years with appropriate component replacements at critical intervals.

(hot water boiler maintenance)

FAQS on hot water boiler maintenance

Q: What is the importance of hot water boiler maintenance?

A: It ensures efficient operation and prevents costly breakdowns. Regular checks extend the boiler's lifespan and maintain safety standards. Neglecting it can lead to energy waste or hazards.

Q: What key tasks should be on a steam boiler maintenance checklist?

A: Essential tasks include testing safety valves and inspecting the burner system. Also, clean the tubes annually and monitor water quality. This checklist guarantees reliability and compliance with regulations.

Q: How often should low pressure steam boiler maintenance be performed?

A: Schedule it monthly for quick inspections and annually for thorough servicing. Focus on sediment removal and pressure gauge calibration. Consistent care avoids operational issues in low-pressure settings.

Q: What signs indicate urgent hot water boiler maintenance is needed?

A: Watch for unusual noises or erratic temperature fluctuations. Also, leaks or poor heating performance demand immediate attention. Addressing these early prevents major repairs.

Q: Can DIY methods cover low pressure steam boiler maintenance?

A: Simple tasks like water level checks can be done yourself. However, complex repairs require certified professionals for safety. Always consult manuals or specialists first.

-

High-Efficiency Biomass Fired Steam Boiler for Industrial Use

NewsJul.24,2025

-

High Efficiency Coal Fired Thermal Oil Boiler for Industrial Heating

NewsJul.23,2025

-

High-Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.22,2025

-

High-Efficiency Commercial Steam Boilers for Sale | Oil & Gas

NewsJul.22,2025

-

Reliable Biomass Thermal Oil Boiler Manufacturers

NewsJul.21,2025

-

Steam Boiler System Diagram & Schematic Efficient Heating Solutions for Industry

NewsJul.08,2025

Related PRODUCTS