डिस . 01, 2024 07:43 Back to list

steam boiler components and functions

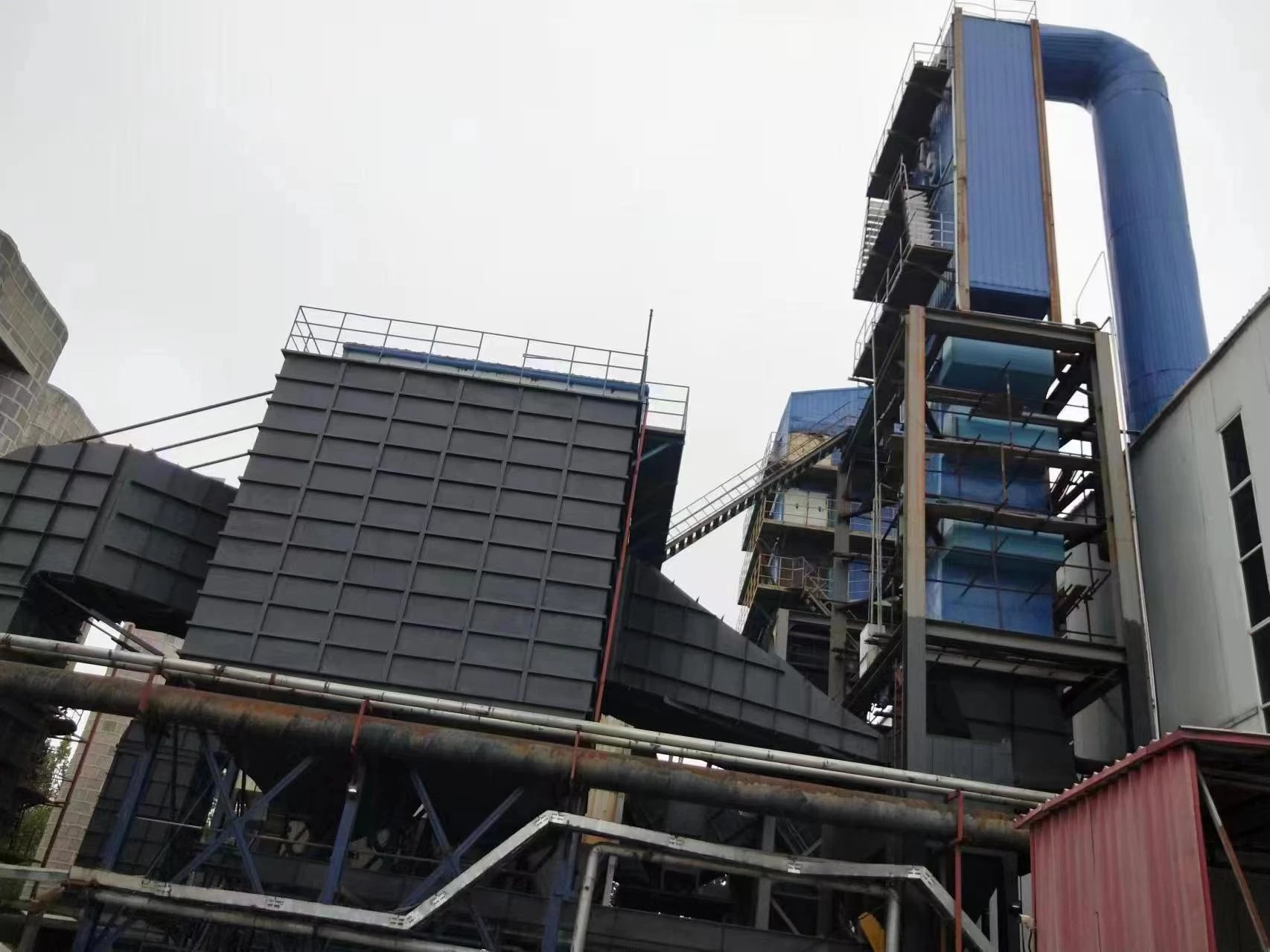

Components and Functions of a Steam Boiler

A steam boiler is a crucial component in various industrial applications, providing thermal energy for processes that require heat. Understanding its components and functions is essential for effective operation and maintenance. This article will delve into the key components of a steam boiler and their respective functions.

1. Boiler Shell

The boiler shell is the outer structure of the steam boiler and serves a critical role in containing the water and steam while withstanding the pressure built inside during operation. It is typically constructed from high-strength steel capable of enduring high temperatures and pressures. The design and integrity of the boiler shell are vital for safety, as any failure can lead to catastrophic results.

2. Heat Exchanger

The heat exchanger is a critical component that transfers heat from the combustion process to the water, converting it into steam. The most common type of heat exchanger in a steam boiler is the fire-tube or water-tube configuration. In a fire-tube boiler, hot gases pass through tubes surrounded by water, whereas, in a water-tube boiler, water flows through tubes heated by gases. Effective heat exchange maximizes thermal efficiency and optimizes energy use.

3. Burner

The burner is responsible for mixing fuel (such as natural gas, oil, or coal) with air to create a combustion flame. The burner’s design is essential for achieving efficient combustion and minimizing emissions. Modern burners often include advanced controls and monitoring systems to ensure optimal fuel-air ratios, thereby enhancing efficiency and performance.

4. Steam Drum

The steam drum is a vital component where steam and water separate. It is located at the top of the boiler and serves as the collection point for generated steam. The steam drum contains various accessories, such as water level gauges and steam separators, to maintain appropriate steam quality and pressure. It also plays a significant role in transporting steam to the end-use application.

steam boiler components and functions

A water feed system is crucial for maintaining the appropriate water level within the boiler. It typically consists of a feedwater pump, which delivers water from an external source to the boiler. Maintaining the correct water level is imperative because low water levels can lead to overheating and potential damage to the boiler, while excessive water can affect steam quality.

6. Blowdown System

The blowdown system is essential for maintaining water quality within the steam boiler. As water is heated and converted to steam, impurities concentrate in the remaining water. To control the buildup of these impurities, the blowdown system allows for the intentional removal of a portion of the water to maintain desired chemical levels. Regular blowdown helps in preventing corrosion and scaling within the boiler.

7. Safety Valves

Safety valves are critical safety features designed to prevent excessive pressure build-up within the boiler. These valves automatically release steam when the pressure exceeds a preset limit, ensuring the boiler operates within safe levels. Regular testing and maintenance of safety valves are essential to guarantee reliability and performance.

8. Control Systems

Modern steam boilers are equipped with sophisticated control systems that regulate various operational parameters, such as pressure, temperature, and water levels. These control systems enhance automation, improve efficiency, and ensure safe operation by allowing real-time monitoring and adjustments.

9. Insulation

Insulation plays a vital role in maintaining energy efficiency by minimizing heat loss from the boiler. Proper insulation reduces energy consumption and helps maintain the desired temperature within the system. It also serves to protect personnel from high surface temperatures, ensuring safety during operation.

Conclusion

In conclusion, the steam boiler is a complex assembly of components, each playing an integral role in its overall function. Understanding these components and their functions is crucial for operators, engineers, and maintenance personnel. Regular monitoring, proper maintenance, and timely inspections are essential to ensure the efficiency, reliability, and safety of steam boiler operations. A well-functioning steam boiler system not only enhances productivity but also contributes to the sustainability and economic efficiency of operations across various industries.

-

Best Steam Boiler Design PDF Free Design Calculation & Diagram Downloads

NewsJun.10,2025

-

Hot Boiler Water Heater Efficient Heating Solutions for Home & Commercial Use

NewsJun.10,2025

-

Steam Boiler Safety Devices High-Quality Protection Valves

NewsJun.10,2025

-

Ultimate Steam Boiler Checklist for Safety & Efficiency

NewsJun.10,2025

-

Optimal Hot Water Boiler Temperature Setting Guide

NewsJun.10,2025

-

Effective Hot Water Boiler Chemical Treatment Protect & Maintain

NewsJun.09,2025

Related PRODUCTS