अक्ट . 11, 2024 09:36 Back to list

steam boiler low water cutoff wiring diagram

Understanding the Wiring Diagram for Low Water Cutoff in Steam Boilers

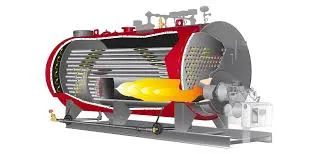

Steam boilers are essential components in various industrial applications, providing heat and power by converting water into steam. However, regardless of the size or design, all steam boilers share one critical safety feature the low water cutoff (LWCO). This device prevents the boiler from operating when the water level falls below a safe threshold, thereby avoiding catastrophic failures. Understanding the wiring diagram for a low water cutoff is crucial for proper installation, troubleshooting, and maintenance of your steam boiler.

What is a Low Water Cutoff?

A low water cutoff is a safety mechanism designed to monitor the water level within a steam boiler. When the water level decreases to a predetermined level, the LWCO activates and triggers the boiler to shut down. This is vital because operating a boiler without sufficient water can lead to overheating, boiler damage, or even explosions.

Components of Low Water Cutoff Wiring

1. Sensors The low water cutoff typically employs sensors that detect the level of water inside the boiler. There are generally two types of sensors used probe sensors and float sensors. Probe sensors can detect water level through electrical conductivity, while float sensors use a physical buoy to gauge water levels.

2. Control System The heart of the LWCO system is its control circuitry, which interprets the signals from the sensors. This includes relays and circuit boards that respond to low water conditions by cutting power to the burner or boiler controls.

3. Power Supply The LWCO system requires a proper power supply for its operation. Typically, this will be a low-voltage AC or DC circuit that powers the sensors and control components.

4. Safety Alarms Many systems also include alarms that alert operators when low water conditions are detected. These alarms can be audible or visual indicators and help ensure immediate attention to the boiler's status.

Understanding the Wiring Diagram

A wiring diagram provides a detailed graphical representation of the electrical connections and components required for a low water cutoff system in a steam boiler. Here are the key elements you should look for

steam boiler low water cutoff wiring diagram

- Power Connections The diagram will clearly illustrate how power enters the LWCO, including connections to the appropriate fuses or circuit breakers.

- Sensor Wiring The wiring for the water level sensors will show how they connect to the control system. Make sure these connections are secure and well-insulated to prevent false readings or shorts.

- Control Circuitry This section of the diagram will explain how signals travel from the sensors to the control unit and how it, in return, influences the burner operation. You may find relays that open or close circuits based on water level inputs.

- Alarm Systems Look for additional components related to alarms that may be linked to the LWCO system. These might be wired in parallel or series with the main control circuit and should be marked clearly on the diagram.

Importance of Correct Wiring

Correct wiring is critical for the functionality and safety of the low water cutoff system. Any errors in the connections can lead to improper device operation, which may result in dangerous situations. It is essential to follow the specific wiring instructions provided by the LWCO manufacturer and ensure that all components are compatible with your boiler system.

Maintenance and Troubleshooting

Regular maintenance and inspection of the wiring and components are necessary to ensure reliable operation. It's crucial to check for any wear and tear, corroded connections, or loose wires that may interfere with the system’s functionality. If the boiler experiences issues, troubleshooting should begin at the low water cutoff wiring to confirm proper operation of the sensors and circuits.

Conclusion

In summary, the low water cutoff wiring diagram is vital for ensuring the safe and effective operation of steam boilers. By understanding its components and how they interconnect, facility managers and maintenance personnel can enhance the reliability of their boiler systems, prevent potential hazards, and promote a safe working environment. Proper installation, vigilant inspection, and proactive maintenance of the LWCO system can significantly reduce risks associated with low water levels in steam boilers.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS