Окт . 01, 2024 17:07 Back to list

Safety Mechanisms for Steam Boilers and Their Importance in Preventing Hazards

Steam Boiler Safety Devices Ensuring Proper Functionality and Safety

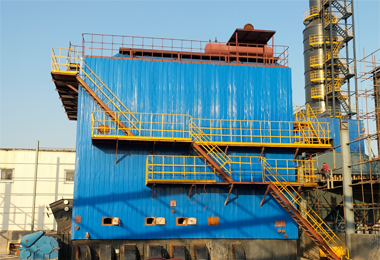

Steam boilers are widely utilized in industrial applications for heating, power generation, and various manufacturing processes. Given their critical role and the potential dangers associated with high-pressure steam, safety devices are essential for their safe operation. This article explores the importance of steam boiler safety devices and their functions in preventing accidents.

One of the primary safety devices in a steam boiler is the pressure relief valve. This device is designed to release excess pressure that builds up within the boiler, preventing potential explosions. When the pressure exceeds a predetermined threshold, the valve opens, allowing steam to escape and thus averting catastrophic failures. Regular maintenance and testing of this valve are crucial to ensure its reliability.

Another vital component is the low-water cutoff. This device monitors the water level within the boiler and will automatically shut down the burner if the water level drops below a safe threshold. Running a boiler without sufficient water can lead to overheating and serious damage, making the low-water cutoff an essential safety feature.

steam boiler safety devices

In addition to these devices, automatic blow-off valves play a key role in maintaining optimal functioning conditions. These valves allow for the removal of accumulated sediments or sludge from the boiler, which can impede efficiency and safety. Regular blow-down procedures help maintain the integrity and efficiency of the boiler system.

Another important safety feature is the fusible plug. Located in the boiler, this device is designed to melt and release steam if the boiler's temperature exceeds a safe level. This prevents overheating and potential explosions by ensuring that the excess steam can escape safely.

Furthermore, regular inspections and adherence to safety regulations are crucial for ensuring that all safety devices are functioning correctly. Operators are responsible for understanding the operational capabilities of their boilers and ensuring that any safety devices are not tampered with or overridden.

In conclusion, steam boiler safety devices are essential for the safe operation of steam systems. By incorporating devices such as pressure relief valves, low-water cutoffs, automatic blow-off valves, and fusible plugs, operators can significantly reduce the risks associated with high-pressure steam. Regular maintenance, inspection, and adherence to safety protocols are critical steps in ensuring that these devices function effectively to protect both personnel and equipment. Proper implementation of safety devices not only enhances safety but also contributes to the efficiency and reliability of steam boiler operations.

-

Oil Fired Hot Water Boilers Sale - High Efficiency & Affordable

NewsJul.31,2025

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

Related PRODUCTS