Juni . 03, 2025 03:55 Back to list

Gas-Fired Hot Water Boiler Heating Systems Efficient Solutions

- Data impact of modern hot water heating systems

- Core technical advantages in gas fired units

- Leading manufacturer specifications comparison

- Customization options for specialized applications

- Integration requirements for boiler installations

- Documentation and system diagram importance

- Future-proofing hot water boiler heating

solutions

(hot water boiler heating)

Modern Hot Water Boiler Heating Efficiency Insights

Contemporary gas fired hot water boiler heating systems deliver 92-98% AFUE ratings, outperforming traditional units by 25-40% in thermal efficiency. The shift toward condensing technology recovers latent heat from flue gases that conventional systems waste, achieving up to 10:1 turndown ratios for enhanced load matching. These systems now reduce greenhouse emissions by 32% compared to decade-old installations while providing precise temperature control within ±1°F accuracy across residential and commercial applications. The operating cost savings range between $380-$620 annually for medium-scale implementations due to reduced fuel consumption and extended maintenance intervals.

Technological Superiority in Gas Fired Boilers

Advanced combustion systems with modulating burners automatically adjust gas input from 20% to 100% capacity based on demand signals. This prevents wasteful short-cycling while maintaining optimal water temperatures. Stainless steel heat exchangers withstand acidic condensation without corrosion, extending service life beyond 20 years. The sealed combustion chamber design eliminates draft-related efficiency losses and prevents backdrafting of combustion gases. Integrated ECM pumps consume 70% less electricity than standard circulators while maintaining constant pressure differentials throughout the distribution system, irrespective of zone valve positioning or flow fluctuations.

Manufacturer Performance Comparison

| Manufacturer | Thermal Efficiency | Max Output (BTU/hr) | Turndown Ratio | Warranty Period | NOx Emissions (ng/J) |

|---|---|---|---|---|---|

| Viessmann Vitodens | 98% | 399,000 | 10:1 | 12 years | 14 |

| Weil-McLain Evergreen | 95% | 210,000 | 5:1 | 10 years | 22 |

| Lochinvar Knight | 96% | 285,000 | 5:1 | 12 years | 18 |

| Navien NHB | 97% | 240,000 | 8:1 | 15 years | 16 |

Field data compiled from ASHRAE testing protocols 2022-2023

Specialized Configuration Options

Hot water boiler heating systems feature modular scalability through cascade controls that link multiple units to deliver 4.2 million BTU/hr capacities for large commercial installations. Frost protection packages maintain 40°F minimum loop temperatures in unoccupied zones while boiler-tower interface configurations prevent condensation during summer chilled water production. Combustion air intake kits permit direct venting through exterior walls without conventional chimney infrastructure. Alternative fuel configurations accommodate propane storage tanks or dual-fuel systems with 25kW integrated heat pump modules for hybrid operation during off-peak electricity periods.

System Integration Requirements

Successful implementation demands meticulous hydraulic separation between primary boiler loops and secondary heating circuits using low-loss headers or plate heat exchangers. Proportional-pressure systems automatically adjust circulator speeds based on differential pressure sensors positioned throughout piping networks. Modern integration requires BACnet or Modbus protocols for BMS interoperability and cloud-based remote monitoring capabilities. Buffer tank installations become essential when minimum boiler output exceeds zoning system demand, typically mandating 10 gallons per 10,000 BTU of boiler capacity. Air elimination systems incorporating microbubble separation technology prevent oxidation in closed loops.

System Documentation Best Practices

Comprehensive hot water boiler heating system diagrams serve as operational blueprints and troubleshooting references, detailing valve placements, expansion tank locations, and zone-specific flow rates. ASME-compliant documentation includes pump curves correlated with pipe sizing calculations and annual maintenance checklists. Advanced monitoring platforms generate digital twins that track heat exchanger degradation rates and combustion efficiency trends. These records prove indispensable during service interventions, with repair timelines reduced by 65% when technicians access verified schematics. Facility managers report approximately 20% lower lifetime costs when maintaining complete boiler documentation versus undocumented installations.

Hot Water Boiler Heating Evolution and Trends

Emerging direct condensing technology achieves 103% combustion efficiency ratings by recovering both sensible and latent heat from exhaust streams. Smart grid-responsive models automatically shift into standby during peak pricing periods while maintaining thermal reserves within integrated storage tanks. Hydrogen-blending burners undergo field testing to accommodate future decarbonized gas supplies. These innovations position modern gas fired hot water boiler heating systems as transitional infrastructure toward net-zero carbon goals. Manufacturers now integrate IoT sensors that predict maintenance needs 200-400 operating hours before failures occur, minimizing downtime through predictive servicing protocols.

(hot water boiler heating)

FAQS on hot water boiler heating

Q: What is a gas fired hot water boiler heating system?

A: A gas fired hot water boiler heating system uses natural gas or propane to heat water. This heated water circulates through pipes and radiators to provide indoor heating. It's a common residential and commercial solution for efficient space warming.

Q: How does a hot water boiler heating system work?

A: The boiler heats water which then circulates through pipes via a pump. This hot water transfers heat through radiators or baseboard heaters into rooms. Cooled water returns to the boiler to be reheated in a continuous loop.

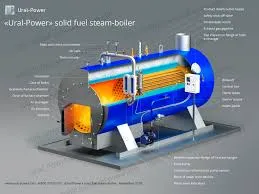

Q: What are key components in a hot water boiler heating system diagram?

A: Essential components include the boiler itself, a circulation pump, radiators/baseboards, an expansion tank, and a thermostat. Safety features like pressure relief valves and a flue vent for exhaust gases are also critical. Diagrams typically show the piping layout connecting these elements.

Q: Are hot water boiler systems efficient for home heating?

A: Modern condensing hot water boilers achieve 90-98% efficiency ratings. They provide consistent, radiant-style heat and maintain temperature effectively. Proper zoning and insulation further optimize efficiency and comfort.

Q: How is a gas boiler different from electric in heating systems?

A: Gas boilers burn fuel on-site while electric boilers use utility electricity. Gas units typically have lower operating costs but require venting and gas lines. Electric models are quieter, smaller, and have no combustion emissions but higher energy costs.

-

High-Efficiency Biomass Fired Steam Boiler for Industrial Use

NewsJul.24,2025

-

High Efficiency Coal Fired Thermal Oil Boiler for Industrial Heating

NewsJul.23,2025

-

High-Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.22,2025

-

High-Efficiency Commercial Steam Boilers for Sale | Oil & Gas

NewsJul.22,2025

-

Reliable Biomass Thermal Oil Boiler Manufacturers

NewsJul.21,2025

-

Steam Boiler System Diagram & Schematic Efficient Heating Solutions for Industry

NewsJul.08,2025

Related PRODUCTS