Dec . 30, 2024 00:19 Back to list

gas steam boiler

Understanding Gas Steam Boilers Efficiency and Applications

Gas steam boilers are critical components in various industrial processes and heating systems, recognized for their efficiency and reliability. These boilers convert water into steam using natural gas or propane as fuel, offering an effective means to generate heat and power. As industries continue to seek sustainable and cost-effective solutions, gas steam boilers remain a popular choice.

How Gas Steam Boilers Work

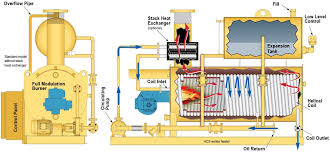

The fundamental operation of a gas steam boiler involves several key components the burner, heat exchanger, steam drum, and control systems. The burner ignites the gas to produce a flame, which heats the water within the boiler. The heat exchanger facilitates the transfer of heat from the flame to the water, raising its temperature and eventually converting it into steam. As the steam is generated, it collects in the steam drum, ready to be channeled for various applications, from heating spaces to driving turbines in power generation.

Modern gas steam boilers are designed with advanced technologies to optimize efficiency and reduce emissions. Many incorporate features such as modulating burners that adjust the flame intensity based on the heating demand. This capability not only improves energy efficiency but also minimizes fuel consumption, resulting in lower operational costs.

Advantages of Gas Steam Boilers

One of the primary advantages of gas steam boilers is their high efficiency. Natural gas is a clean-burning fuel, and when utilized in these boilers, it often results in lower greenhouse gas emissions compared to oil or coal-fired boilers. Moreover, gas steam boilers tend to have quicker start-up times and can reach operating temperatures faster, making them suitable for applications requiring immediate heat.

gas steam boiler

Another significant advantage is their versatility in application. Gas steam boilers are widely used in industries such as food processing, chemical manufacturing, and even residential heating systems. In food processing, for instance, steam is commonly used for cooking, sterilizing, and cleaning equipment. In chemical plants, steam is essential for various processes, including reaction and distillation.

Maintenance and Safety

While gas steam boilers offer numerous benefits, proper maintenance is crucial to ensure their longevity and safe operation. Regular inspections and servicing can prevent potential issues such as leaks or malfunctions. Operators should regularly check pressure gauges, water levels, and the condition of safety valves. Implementing a rigorous maintenance schedule can not only enhance performance but also ensure compliance with safety regulations.

Safety is paramount in operating gas steam boilers. They are equipped with multiple safety features, including low-water cut-off devices and pressure relief valves that prevent excessive pressure buildup. Operators must be trained to recognize potential hazards and respond to emergencies effectively, ensuring a safe working environment.

Conclusion

In summary, gas steam boilers are integral to a wide range of industrial applications, offering efficiency, versatility, and environmental benefits. As industries continue to evolve, the demand for advanced, eco-friendly heating solutions will likely increase, positioning gas steam boilers as a viable option for meeting energy needs. By prioritizing maintenance and safety, operators can maximize the advantages of these systems, contributing to a sustainable future in energy consumption. As technology advances, we can expect even more innovations in the design and functionality of gas steam boilers, further underscoring their importance in modern industrial operations.

-

High-Efficiency On-Off Steam Boiler for Reliable Heating Solutions Compare with Off Boiler Water Heaters & Steam Generators

NewsJun.24,2025

-

Best Steam Boiler Design PDF Free Design Calculation & Diagram Downloads

NewsJun.10,2025

-

Hot Boiler Water Heater Efficient Heating Solutions for Home & Commercial Use

NewsJun.10,2025

-

Steam Boiler Safety Devices High-Quality Protection Valves

NewsJun.10,2025

-

Ultimate Steam Boiler Checklist for Safety & Efficiency

NewsJun.10,2025

-

Optimal Hot Water Boiler Temperature Setting Guide

NewsJun.10,2025

Related PRODUCTS