Dec . 13, 2024 11:24 Back to list

steam boiler system design

Steam Boiler System Design Key Considerations and Principles

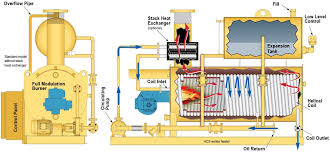

The steam boiler system is a vital component in various industrial processes, providing essential steam for heating, power generation, and other applications. Designing an efficient and reliable steam boiler system involves numerous considerations that ensure operational efficiency, safety, and environmental compliance. This article outlines the key aspects to consider in the steam boiler system design.

1. Understanding Boiler Types

The design of a steam boiler system starts with understanding the types of boilers available. The two main categories are fire-tube and water-tube boilers. Fire-tube boilers contain hot gases that pass through tubes surrounded by water, making them suitable for low to medium pressure applications. In contrast, water-tube boilers have water-filled tubes through which hot gases pass, making them ideal for high-pressure and high-capacity applications. Choosing the right type of boiler depends on the specific requirements of the industrial process, including steam pressure and capacity needs.

2. Fuel Selection

The type of fuel used in a steam boiler significantly impacts its design. Common fuels include natural gas, fuel oil, coal, and biomass. The choice of fuel affects the boiler's efficiency, emissions profile, and overall environment-related considerations. For instance, natural gas is often favored due to its cleaner combustion compared to coal. However, renewable fuel options, such as biomass, are gaining traction as industries strive for sustainability. The availability and cost of the fuel source also influence the overall design and operational costs of the steam boiler system.

3. Efficiency Considerations

Efficiency is a critical factor in steam boiler system design. High-efficiency boilers can reduce fuel consumption and operating costs. To achieve these efficiency levels, features such as economizers, which recover waste heat from flue gases, and advanced control systems that optimize fuel-to-steam conversion are essential. Additionally, regular maintenance schedules can help sustain efficiency by minimizing fouling and wear in key components.

4. Pressure and Temperature Controls

Designing a steam boiler system requires careful consideration of pressure and temperature controls to maintain safe and efficient operations. Appropriate safety valves, pressure gauges, and temperature sensors should be installed to monitor and control these parameters. The design must include fail-safes and redundancy, enabling the system to maintain stability in challenging operating conditions.

steam boiler system design

5. Safety Protocols

Safety is paramount in any steam boiler design. The high pressures and temperatures involved pose significant risks if not managed correctly. Boiler designs must adhere to stringent safety standards and regulations, such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. Incorporating features like blow-off valves, safety interlocks, and automatic shutdown systems can prevent accidents and ensure worker safety.

6. Water Treatment

Water quality is a crucial aspect of steam boiler operation. Poor water quality can lead to scale formation, corrosion, and other issues that reduce efficiency and lifespan. Therefore, designing an effective water treatment system is essential. This may involve mechanical filtration, chemical treatments, and regular testing to ensure the water used in the boiler meets required specifications.

7. Environmental Concerns

With increasing environmental regulations, steam boiler system design should account for emissions and waste management. Implementing advanced combustion technologies and emission control systems can significantly mitigate environmental impacts. Options include flue gas scrubbers, selective catalytic reduction (SCR) for nitrogen oxides (NOx) control, and carbon capture technologies, aimed at minimizing the boiler's carbon footprint.

8. Integration with Other Systems

Lastly, designing a steam boiler system should also consider its integration with other processes within the facility. Close cooperation with other systems, such as heating systems, turbines for power generation, and manufacturing processes, can enhance overall energy efficiency and return on investment.

Conclusion

The design of a steam boiler system encompasses a wide range of factors, from boiler type and fuel selection to safety protocols and environmental considerations. Each element must work harmoniously to ensure an efficient, safe, and sustainable operation. By paying careful attention to these diverse aspects, engineers can create robust steam boiler systems that meet the demands of modern industrial applications.

-

Best Steam Boiler Design PDF Free Design Calculation & Diagram Downloads

NewsJun.10,2025

-

Hot Boiler Water Heater Efficient Heating Solutions for Home & Commercial Use

NewsJun.10,2025

-

Steam Boiler Safety Devices High-Quality Protection Valves

NewsJun.10,2025

-

Ultimate Steam Boiler Checklist for Safety & Efficiency

NewsJun.10,2025

-

Optimal Hot Water Boiler Temperature Setting Guide

NewsJun.10,2025

-

Effective Hot Water Boiler Chemical Treatment Protect & Maintain

NewsJun.09,2025

Related PRODUCTS