Dec . 19, 2024 11:18 Back to list

Design Principles for Efficient and Safe Steam Boiler Systems in Industrial Applications

Steam Boiler Design Principles, Materials, and Efficiency

Steam boilers have long been essential components in various industries, providing efficient heat and power for numerous applications. The design of a steam boiler involves several critical considerations that ensure effectiveness, safety, and efficiency. This article will explore the fundamental principles of steam boiler design, the materials commonly used, and key factors influencing boiler efficiency.

Principles of Steam Boiler Design

At its core, a steam boiler is designed to convert water into steam using heat energy. The fundamental principle behind steam production is the phase change of water from liquid to vapor. This phase change occurs at a specific pressure and temperature, known as the saturation point. Boilers are engineered to operate efficiently within predefined parameters to maximize the steam output while minimizing energy consumption.

The primary types of steam boilers include fire-tube and water-tube boilers. Fire-tube boilers consist of a series of tubes surrounded by water, with combustion gases passing through the tubes. This design is straightforward and effective for low-pressure applications. In contrast, water-tube boilers have water-filled tubes that are heated by external flue gases, making them suitable for high-pressure and high-temperature applications. The choice between these two designs depends on the specific heating requirements, space constraints, and operational pressures of the application.

Materials Used in Boiler Construction

The materials chosen for steam boiler construction are crucial to ensuring safety, durability, and efficiency. Typically, steel is the primary material used due to its high strength and ability to withstand high temperatures and pressures. Carbon steel is commonly employed for fire-tube boilers, while alloy steels are preferred in water-tube designs, especially in situations requiring higher corrosion resistance and thermal fatigue endurance.

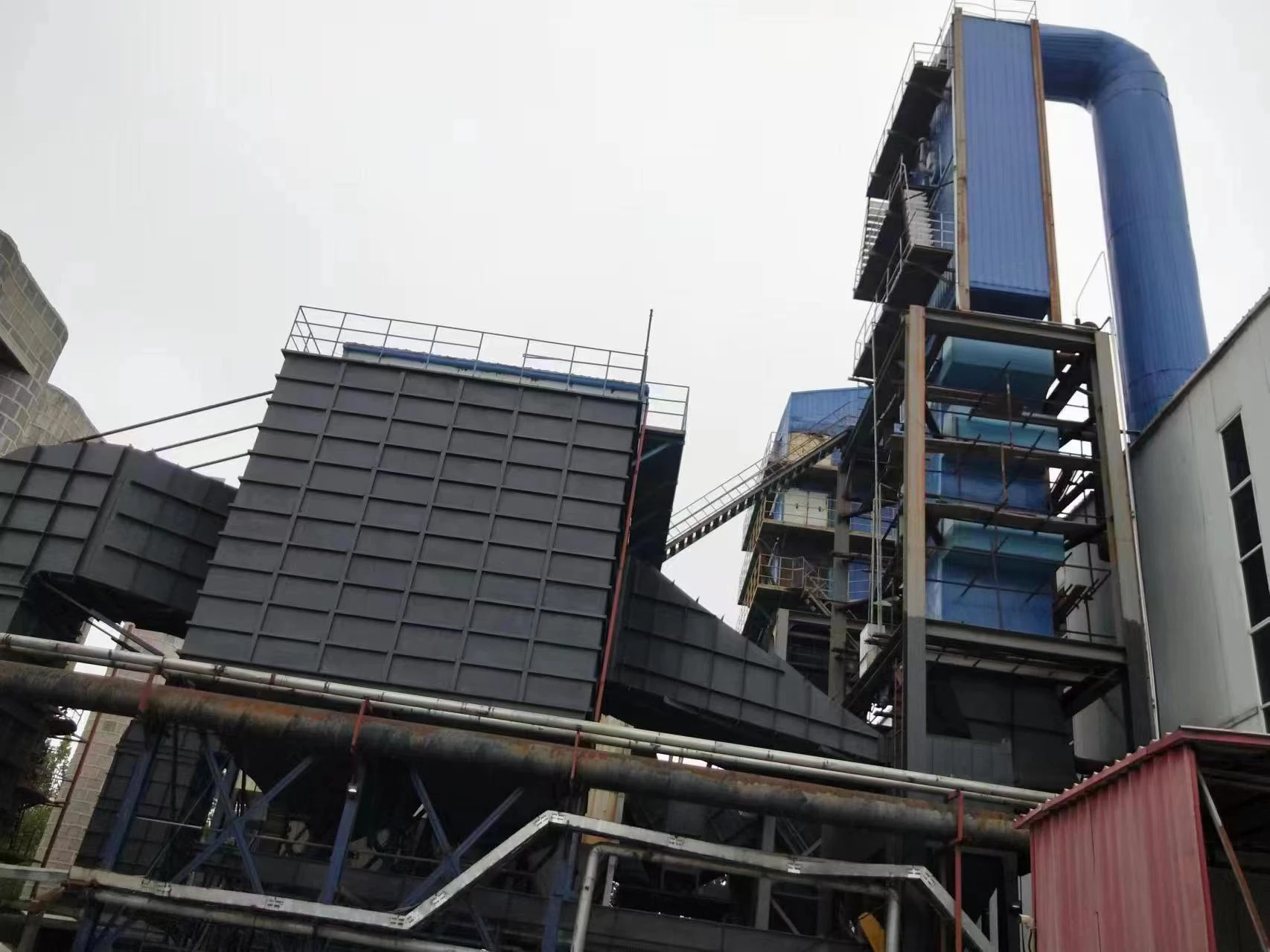

steam boiler design

Furthermore, the boiler's insulation is critical to reduce heat loss and improve efficiency. High-temperature insulation materials, such as calcium silicate or ceramic fiber, are often used to cover boiler surfaces and prevent heat from escaping into the environment. Proper insulation not only enhances energy efficiency but also ensures safety by minimizing the risk of burns or other heat-related injuries.

Factors Influencing Boiler Efficiency

The efficiency of a steam boiler can be influenced by several factors, including design, operation, maintenance, and the quality of fuel used. One of the key design considerations is the boiler's combustion chamber. A well-designed combustion chamber allows for complete fuel combustion, reducing unburned fuel and increasing energy efficiency.

Another essential factor is the boiler's heat recovery systems, which capture and reuse waste heat. Economizers and heat exchangers can be integrated into boiler systems to recover heat from flue gases, significantly improving overall efficiency by preheating the feedwater.

Regular maintenance is also vital for ensuring optimal boiler performance. Scheduled inspections, cleaning of heat transfer surfaces, and monitoring of safety devices prevent inefficiencies and prolong the boiler's lifespan. Over time, scale build-up and corrosion can hinder the heat transfer process, resulting in decreased performance and increased fuel consumption.

Conclusion

In conclusion, steam boiler design is a multifaceted process that requires careful consideration of fundamental principles, material selection, and operational efficiency. The choice of boiler type and construction materials significantly impacts its performance, durability, and safety. By focusing on efficient design practices and proper maintenance, industries can maximize the benefits of steam boilers, ensuring they meet both operational demands and environmental standards. As technology continues to advance, the evolution of steam boiler design will play a crucial role in enhancing energy efficiency and sustainability across various sectors.

-

Oil Fired Hot Water Boilers Sale - High Efficiency & Affordable

NewsJul.31,2025

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

Related PRODUCTS