Eyl . 22, 2024 21:44 Back to list

types of coal fired steam boiler

Types of Coal-Fired Steam Boilers

Coal-fired steam boilers play a crucial role in various industrial applications, generating steam for processes ranging from power generation to food processing. Understanding the different types of coal-fired steam boilers is essential for industries to select the most suitable system that meets their operational needs and efficiency criteria. This article will explore the main types of coal-fired steam boilers commonly in use today.

1.Fire-Tube Boilers

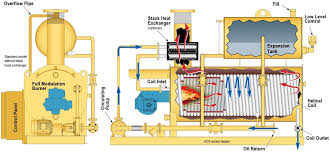

Fire-tube boilers are one of the most traditional designs. In this type, hot gases produced by burning coal pass through a series of tubes submerged in water. The heat from these gases transfers to the water, generating steam. Fire-tube boilers are known for their simplicity and ease of maintenance. They are generally suitable for lower pressure steam applications and are favored in smaller industrial settings due to their compact size and lower initial investment costs.

In contrast to fire-tube boilers, water-tube boilers feature water-filled tubes that are heated by flames produced in the furnace. This design allows for much higher pressure capabilities and faster steam production, making them ideal for large industrial applications. Water-tube boilers can handle the high-temperature and high-pressure demands of large power plants, offering better efficiency and flexibility in operation. Furthermore, they can be designed to burn various fuels, including different grades of coal.

types of coal fired steam boiler

3.Stoker-Fired Boilers

Stoker-fired boilers utilize a mechanical device known as a stoker to feed coal into the furnace. This method allows for a continuous and controlled supply of fuel, providing consistent heat generation. Stoker systems can be classified into different types—such as chain grate stokers, undersized stokers, and spreader stokers—each designed for specific types of coal and combustion requirements. Stoker-fired boilers are known for their efficiency in burning low-grade coals, making them a popular choice in utility and industrial settings.

4.Circulating Fluidized Bed (CFB) Boilers

CFB boilers represent a newer technology that allows for efficient coal combustion at lower temperatures, minimizing emissions significantly. In CFB boilers, coal particles are suspended in a fast-moving stream of hot air, creating a fluidized state that enhances combustion efficiency. This technology is highly adaptable and makes use of a wide variety of coal types, including those with high ash content. CFBs are favored for their low environmental impact and their ability to generate electricity with high thermal efficiency.

Conclusion

Choosing the right type of coal-fired steam boiler is essential for maximizing efficiency, ensuring safety, and maintaining regulatory compliance. Fire-tube and water-tube boilers each have their unique advantages, while stoker-fired and CFB technologies present modern solutions to meet the demands of industrial processes. As environmental concerns continue to rise, many industries are also exploring cleaner coal technologies and alternatives to coal to reduce their carbon footprints and adhere to more stringent emission regulations. Thus, the evolution of coal-fired steam boilers will likely continue, driven by technological advancements and a growing commitment to sustainability.

-

Best Steam Boiler Design PDF Free Design Calculation & Diagram Downloads

NewsJun.10,2025

-

Hot Boiler Water Heater Efficient Heating Solutions for Home & Commercial Use

NewsJun.10,2025

-

Steam Boiler Safety Devices High-Quality Protection Valves

NewsJun.10,2025

-

Ultimate Steam Boiler Checklist for Safety & Efficiency

NewsJun.10,2025

-

Optimal Hot Water Boiler Temperature Setting Guide

NewsJun.10,2025

-

Effective Hot Water Boiler Chemical Treatment Protect & Maintain

NewsJun.09,2025

Related PRODUCTS