Mar . 05, 2025 05:57 Back to list

Biomass fired steam boiler

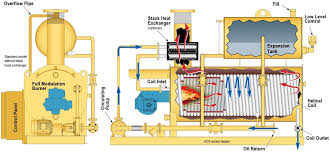

A steam boiler is an essential component in various industries, providing an efficient way to generate steam for power, heating, and cooling applications. The success of a steam boiler system largely depends on its components and their respective functions. Understanding these components and their roles not only helps maximize efficiency but also ensures safety and longevity of the system. Let's delve into the key components of a steam boiler and their crucial functions.

Feed Pumps are used to supply water to the boiler. They must be robust and capable of operating under high pressure to consistently meet the boiler's demand for water, especially during peak loads. The reliability and efficiency of feed pumps are essential for sustaining continuous boiler operation. Air Preheaters are employed to increase the combustion air temperature using residual heat from flue gases. Warmer air enhances the combustion efficiency and performance of the boiler, making air preheaters an important component for energy conservation. The Control Systems are the brains of the boiler operation. Modern control systems allow for precise regulation of different parameters such as pressure, temperature, and water levels. Advanced systems integrated with IoT technology provide real-time data analytics, remote monitoring, and predictive maintenance capabilities. The Blowdown System is crucial for maintaining water quality within the boiler. Through controlled removal of water, this system eliminates impurities and dissolved solids that could otherwise cause scaling and corrosion, which adversely affect the boiler’s efficiency and longevity. Finally, Insulation is used extensively in steam boilers to minimize heat loss. Proper insulation ensures that the energy produced by the boiler is used effectively and not wasted through radiation losses. High-quality insulation materials provide a significant boost in energy efficiency while also protecting personnel from exposure to high temperatures. Understanding the components and functions of a steam boiler is essential for anyone involved in their operation, maintenance, or design. Each component is interconnected, and their collective performance dictates the overall efficiency, safety, and reliability of the entire steam boiler system. By leveraging expertise in selecting, operating, and maintaining these components, industries can maximize productivity, ensure operational safety, and achieve cost-effective energy usage.

Feed Pumps are used to supply water to the boiler. They must be robust and capable of operating under high pressure to consistently meet the boiler's demand for water, especially during peak loads. The reliability and efficiency of feed pumps are essential for sustaining continuous boiler operation. Air Preheaters are employed to increase the combustion air temperature using residual heat from flue gases. Warmer air enhances the combustion efficiency and performance of the boiler, making air preheaters an important component for energy conservation. The Control Systems are the brains of the boiler operation. Modern control systems allow for precise regulation of different parameters such as pressure, temperature, and water levels. Advanced systems integrated with IoT technology provide real-time data analytics, remote monitoring, and predictive maintenance capabilities. The Blowdown System is crucial for maintaining water quality within the boiler. Through controlled removal of water, this system eliminates impurities and dissolved solids that could otherwise cause scaling and corrosion, which adversely affect the boiler’s efficiency and longevity. Finally, Insulation is used extensively in steam boilers to minimize heat loss. Proper insulation ensures that the energy produced by the boiler is used effectively and not wasted through radiation losses. High-quality insulation materials provide a significant boost in energy efficiency while also protecting personnel from exposure to high temperatures. Understanding the components and functions of a steam boiler is essential for anyone involved in their operation, maintenance, or design. Each component is interconnected, and their collective performance dictates the overall efficiency, safety, and reliability of the entire steam boiler system. By leveraging expertise in selecting, operating, and maintaining these components, industries can maximize productivity, ensure operational safety, and achieve cost-effective energy usage.

Share

Latest News

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS

Copyright © 2025 HEBEI HONGZE BOILER MANUFACTURING CO., LTD. All Rights Reserved. Sitemap | Privacy Policy