Dec . 18, 2024 20:56 Back to list

1000 kg hr steam boiler

Understanding the 1000 kg/hr Steam Boiler Efficiency and Applications

Steam boilers are essential components in various industrial processes, providing the necessary heat for applications ranging from power generation to manufacturing. Among various models, the 1000 kg/hr steam boiler stands out due to its efficiency and versatility. This article explores the important aspects of the 1000 kg/hr steam boiler, including its design, functionality, applications, and environmental considerations.

Design and Construction

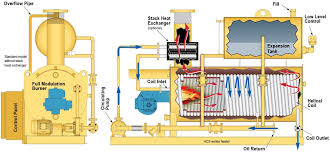

The design of a 1000 kg/hr steam boiler is engineered to handle substantial pressure and thermal loads. Typically, these boilers are categorized as either fire-tube or water-tube boilers.

Fire-Tube Boilers In fire-tube boilers, hot gases produced by combustion pass through tubes that are submerged in water. Air and fuel are burned in a furnace, and the resulting hot gases flow through the tubes, heating the water in the surrounding shell. This type is known for its simplicity and ease of maintenance.

Water-Tube Boilers Conversely, water-tube boilers feature water-filled tubes that are heated externally by combustion gases. These are often favored for high-pressure applications due to their ability to generate steam quickly and efficiently.

Efficiency and Performance

The efficiency of a steam boiler is a critical factor that determines its operational cost and environmental impact. The 1000 kg/hr steam boiler is designed with advanced technology to achieve high thermal efficiency, often exceeding 90%. Factors that contribute to its efficiency include

1. Insulation Proper thermal insulation minimizes heat loss. 2. Automatic Controls Modern steam boilers come equipped with computerized control systems that optimize fuel consumption and steam production. 3. Heat Recovery Systems Some designs incorporate economizers or condensate return systems that recover waste heat or condensate, further enhancing efficiency.

Applications of the 1000 kg/hr Steam Boiler

1000 kg hr steam boiler

The versatility of a 1000 kg/hr steam boiler allows it to be utilized in a variety of industries

1. Food Processing In the food industry, steam is essential for processes such as cooking, sterilization, and pasteurization. A 1000 kg/hr boiler is ideal for medium-sized food processing operations, helping maintain product quality and safety.

2. Textile Industry The textile sector employs steam for dyeing, finishing, and pressing fabrics. A steam boiler of this capacity ensures a steady supply of steam, which is vital for maintaining production efficiency.

3. Chemical Production The chemical industry often requires steam for heating, distillation, and other process operations. A 1000 kg/hr steam boiler can meet the demands of continuous production while ensuring process safety.

4. Power Generation Smaller power plants and combined heat and power (CHP) systems often use steam boilers to generate electricity in addition to providing heating for buildings or industrial processes.

Environmental Considerations

With growing concerns about environmental sustainability, modern steam boilers are engineered to comply with stringent emission regulations. Many 1000 kg/hr steam boilers are designed to reduce emissions of nitrogen oxides (NOx) and sulfur oxides (SOx), utilizing advanced combustion technologies and air-fuel mixing techniques.

Additionally, the trend towards renewable energy sources is influencing the design of steam boilers. Biomass and other alternative fuels can be used, reducing the carbon footprint of steam production. Emphasizing the importance of energy efficiency, these boilers contribute to sustainability efforts within industries.

Conclusion

In summary, the 1000 kg/hr steam boiler is a vital asset for many industries, providing efficiency, reliability, and operational flexibility. With its robust design, it can effectively meet the steam demands of various applications, from food processing to chemical manufacturing. As industries increasingly prioritize energy efficiency and environmental sustainability, the advancement of steam boiler technology ensures that the 1000 kg/hr boiler will remain a key player in industrial heating for years to come. Whether through improved efficiency metrics or reduced emissions, the future of steam boilers is aligned with the broader goals of sustainable industrial practices.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS