Sep . 24, 2024 09:34 Back to list

Cost Analysis of a 3 Ton Boiler and Related Expenses

Understanding the Price of 3% Ton Boiler Factors and Considerations

When considering industrial machinery, especially heating solutions, understanding the costs involved is crucial for businesses. One common type of heating system utilized in various sectors is the boiler. In this article, we'll specifically delve into the price of a 3-ton boiler, highlighting the factors influencing its cost and the implications for potential buyers.

What is a 3-Ton Boiler?

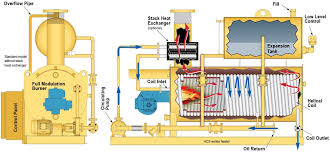

A 3-ton boiler refers to a unit's capacity to produce steam or heat. In general terms, ton is a measurement of the heating efficiency of a boiler, with one ton equating to around 12,000 BTUs (British Thermal Units) of heating power. This metric is particularly important for industries requiring substantial heat output, such as manufacturing, food processing, and chemical plants.

Price Range and Factors Affecting Costs

The price of a 3-ton boiler can vary significantly based on several factors. Generally, the cost can range from $5,000 to $15,000 or even more, depending on the specifications. Understanding the elements that contribute to this price variation is essential for making an informed purchasing decision.

1. Type of Boiler Different types of boilers cater to different needs. For example, fire-tube boilers are generally less expensive compared to water-tube boilers. The choice between a gas, oil, electric, or biomass boiler will also influence the price. Each type has its own advantages and operating costs, which should be considered.

2. Brand and Manufacturer The reputation of the brand plays a significant role in pricing. Established brands with a history of reliability and service may command higher prices. However, investing in a reputable brand often pays off in terms of longevity and efficiency.

3 ton boiler price

3. Energy Efficiency Boilers with higher energy efficiency ratings typically have a higher upfront cost but can lead to lower operational costs over time. Energy-efficient models may qualify for rebates or incentives, offsetting some of the initial investment.

4. Installation Costs The purchase price of the boiler is not the only cost factor. Installation expenses can vary based on the complexity of the setup, location, and any additional equipment needed. It's important to obtain quotes from certified professionals to get a clearer picture of overall costs.

5. Maintenance and Operating Costs While not a direct factor in the purchasing price, long-term maintenance and operational costs should be considered. A cheaper boiler may incur higher running expenses, making it more expensive in the long run.

6. Customization and Features Additional features such as advanced control systems, automated controls, and safety features may inflate the cost. Buyers should assess these options based on their specific needs and budget constraints.

Conclusion

Investing in a 3-ton boiler is a significant decision that necessitates careful consideration of various factors that influence its price. While the initial cost can vary widely, factors such as the type of boiler, brand reputation, energy efficiency, installation costs, and long-term maintenance should all be weighed.

Ultimately, businesses should prioritize finding a boiler that not only meets their heating requirements but also offers reliability and energy efficiency over time. By doing so, they can ensure that their investment is sound and serves their operational needs effectively for years to come.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS