Nov . 14, 2024 07:13 Back to list

high pressure steam boiler psi

Understanding High Pressure Steam Boilers PSI Considerations

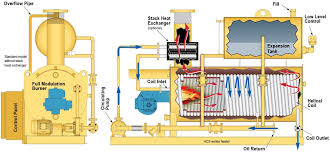

High-pressure steam boilers are critical components in various industrial applications, providing the necessary steam for processes ranging from power generation to heating in large facilities. When discussing high-pressure steam boilers, one term that frequently arises is PSI, which stands for pounds per square inch. This measurement is crucial for understanding the operational capabilities and safety of a steam boiler.

Understanding High Pressure Steam Boilers PSI Considerations

One of the primary advantages of high-pressure steam systems is their ability to transport significant amounts of energy through steam. The steam produced at higher pressures can drive turbines in power plants or provide heat for large-scale heating projects more efficiently than lower pressure systems. Additionally, the higher temperature of the steam allows for quicker heat transfer rates, making these systems particularly advantageous in manufacturing processes that require rapid heating.

high pressure steam boiler psi

However, operating at high pressures also necessitates rigorous safety measures. As pressure increases, so do the risks associated with steam boilers. High-pressure systems must be equipped with multiple safety features, including pressure relief valves, state-of-the-art control systems, and regular maintenance schedules to prevent catastrophic failures. The overall integrity of the boiler material and design is critical; manufacturers adhere to strict standards to ensure that steam boilers can withstand the intense conditions of high-pressure operation.

In addition to safety, operational efficiency is significantly influenced by the boiler's design and the materials used. High-quality steel and advanced insulation techniques are essential to minimize heat loss and maximize performance. Maintenance practices also play a vital role; proper water treatment is necessary to prevent scale buildup and corrosion, both of which can lead to decreased efficiency and increased wear and tear on the equipment.

Another crucial factor to consider is compliance with regulatory standards. Many countries have stringent regulations governing the operation of high-pressure steam boilers. Operators must ensure that their systems meet these standards to avoid penalties, ensure safety, and enhance reliability.

In conclusion, high-pressure steam boilers are essential for many industrial applications, with PSI being a pivotal measurement that reflects their operational capacity. While these systems offer numerous advantages in terms of efficiency and energy output, they also present challenges in terms of safety and maintenance. Operators must remain vigilant in managing these factors to ensure safe and efficient operation. As industries continue to evolve, the role of high-pressure steam boilers will remain vital in meeting energy demands while adhering to safety and regulatory standards.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS