Nov . 05, 2024 04:00 Back to list

hot water boiler operating temperature

Understanding Hot Water Boiler Operating Temperature

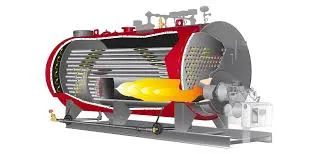

Hot water boilers are essential components in residential, commercial, and industrial heating systems. They generate hot water for various applications, including space heating, domestic hot water supply, and industrial processes. One of the critical aspects of operating a hot water boiler effectively and safely is maintaining the correct operating temperature. This article explores the importance of operating temperatures, the factors that influence them, and the implications of improper temperature management.

Importance of Operating Temperature

The operating temperature of a hot water boiler directly affects its efficiency, safety, and longevity. An optimal temperature ensures that the boiler operates within its designed parameters, maximizing heat transfer efficiency and minimizing energy waste. Generally, hot water boilers operate between 120°F and 180°F (49°C to 82°C), but this range can vary depending on specific applications and system designs.

Maintaining the correct temperature is vital to prevent the risk of overheating, which can lead to pressure buildup and potentially dangerous conditions, such as boiler explosions. On the other hand, operating at too low a temperature can result in insufficient heating, leading to discomfort and increased heating costs as the system works harder to meet demand.

Factors Influencing Operating Temperature

Several factors influence the operating temperature of a hot water boiler, including boiler type, intended use, system design, and environmental conditions.

1. Boiler Type Different types of boilers have different temperature settings. For instance, a residential boiler designed for heating may operate at lower temperatures compared to industrial boilers, which are built to handle higher temperatures and pressures.

2. Intended Use The specific application determines the ideal operating temperature. For example, a boiler used for space heating in a home might operate between 140°F and 160°F (60°C to 71°C), while a boiler used for commercial washing may require higher temperatures to ensure sanitary conditions.

3. System Design The layout of the heating system, including the distance between the boiler and heating elements, affects the required operating temperature. A system with long piping may need to operate at a higher temperature to compensate for heat loss during distribution.

4. Environmental Conditions External temperatures and insulation levels also play a role. In colder climates, boilers may need to work harder and maintain higher temperatures to provide adequate heating.

hot water boiler operating temperature

Implications of Improper Temperature Management

Improper management of a hot water boiler's operating temperature can lead to several challenges. If the water temperature is set too high, not only is there a risk of scalding and safety hazards, but the boiler may also experience increased wear and tear, leading to costly repairs and a reduced lifespan. Conversely, operating at low temperatures can result in inadequate heating and higher energy bills.

Additionally, operating a boiler at temperatures below the recommended levels can cause condensation in flue gases, leading to corrosive damage to the boiler and the exhaust system. This scenario is particularly relevant in condensing boilers, which are designed to operate efficiently at lower temperatures.

Best Practices for Temperature Management

To ensure optimal operation, several best practices can be employed

1. Regular Maintenance Routine maintenance checks by qualified technicians can help ensure that the boiler operates at the correct temperature and efficiency.

2. Temperature Monitoring Installing temperature gauges and automated controls can help maintain the desired temperature range, adjusting automatically based on demand.

3. Proper Insulation Insulating pipes and the boiler itself can minimize heat loss, allowing the system to operate at lower temperatures efficiently.

4. User Education Educating users about the importance of temperature settings and what the effectiveness and efficiency of their heating systems means can promote better practices.

Conclusion

Understanding and managing the operating temperature of hot water boilers is critical for safety, efficiency, and longevity. By recognizing the factors influencing temperature and implementing best practices, users can ensure their systems operate optimally while minimizing risks and costs associated with improper temperature management. A well-maintained hot water boiler not only provides reliable heat but also contributes to long-term energy savings and a safer environment.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS