Dec . 03, 2024 10:23 Back to list

how much does a steam boiler cost

How Much Does a Steam Boiler Cost?

When it comes to industrial processes, steam boilers play a crucial role in providing the necessary heat and pressure for a variety of applications. Industries ranging from power generation and food processing to pharmaceuticals and chemical manufacturing rely heavily on steam boilers. However, one of the most common questions businesses ask is How much does a steam boiler cost?

Factors Influencing the Cost of Steam Boilers

The price of a steam boiler can vary significantly based on several factors

. Understanding these factors can help businesses make informed decisions when purchasing and operating steam boilers.1. Type of Boiler Steam boilers are available in various configurations, including fire-tube, water-tube, and modular designs. Fire-tube boilers tend to be less expensive upfront but may require more fuel and maintenance over their lifespan compared to water-tube boilers, which are generally more efficient and have a higher upfront cost. Modular boilers, while pricier, can offer greater flexibility and efficiency, allowing companies to scale their heating capacity as needed.

2. Capacity The capacity of a boiler, typically measured in horsepower or BTUs (British Thermal Units), directly impacts its cost. Larger boilers capable of producing more steam will generally cost more than smaller models. It’s essential to accurately assess the steam needs of your operation to avoid overspending on unnecessary capacity or, conversely, underestimating your needs and risking operational inefficiencies.

3. Fuel Source The type of fuel a boiler uses—natural gas, oil, coal, or biomass—also influences its cost. Gas-fired boilers are often more economical and environmentally friendly, leading to lower overall operating costs. In contrast, oil or coal-fired boilers may have higher maintenance requirements and fuel costs, contributing to a higher total cost of ownership.

4. Installation Costs The initial costs of a steam boiler do not end with the purchase price alone. Installation costs can add a considerable amount to the overall investment. Factors that affect installation costs include location, accessibility of the site, piping needs, and any required modifications to existing systems. It’s crucial to get a detailed estimate from installation professionals to avoid surprises.

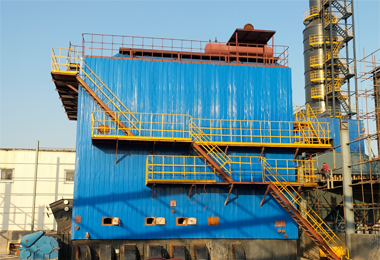

how much does a steam boiler cost

5. Efficiency Ratings Higher efficiency ratings often lead to higher prices. However, purchasing a more efficient boiler may yield lower fuel consumption and operational costs over time. Energy-efficient steam boilers are increasingly becoming a standard due to tighter regulatory standards and a growing focus on reducing carbon footprints.

6. Maintenance and Operating Costs While some boilers may have a lower initial cost, ongoing maintenance and operational efficiency can significantly impact total expenses over the boiler's lifespan. Considering factors such as warranty coverage, expected lifespan, and routine maintenance needs is essential when evaluating the overall cost of ownership.

Average Cost of Steam Boilers

On average, steam boilers can range between $3,000 and $30,000 or more, depending on the factors discussed above. Smaller, less powerful fire-tube boilers may start at the lower end of that range, while larger, more efficient water-tube boilers can easily exceed $30,000. Additionally, specialized applications or custom-built boilers may come with much higher price tags.

Long-Term Considerations

Investing in a steam boiler is not solely about the purchase price. Businesses must consider long-term operating costs, including fuel efficiency, maintenance frequency, and replacement parts availability. Conducting a comprehensive cost-benefit analysis can reveal which models and configurations will provide the best return on investment.

Conclusion

Deciding on a steam boiler involves careful consideration of various factors that influence both initial and ongoing costs. The price range may seem daunting, but understanding the specific needs of your operation—alongside factors like efficiency, fuel source, and maintenance—will allow you to make a more informed decision. Potential buyers are encouraged to compare multiple models, consult with industry experts, and perform thorough research to find a solution that aligns with their operational needs and financial constraints. By investing wisely, businesses can ensure enhanced productivity and efficiency for years to come.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS