Nov . 12, 2024 20:00 Back to list

industrial steam system

Understanding Industrial Steam Systems Efficiency and Applications

Industrial steam systems play a pivotal role in various sectors, including manufacturing, food processing, pharmaceuticals, and energy generation. These systems produce and utilize steam, which is a vital form of energy used for heating, power generation, and numerous industrial processes. Comprehending the intricacies of steam systems can lead to significant enhancements in operational efficiency, cost savings, and environmental sustainability.

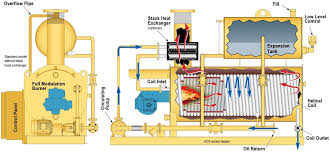

At the core of an industrial steam system is the boiler, which generates steam by heating water. The efficiency of the boiler is crucial as it directly impacts fuel consumption and operational costs. Modern boilers are designed to optimize fuel use while minimizing emissions, thus adhering to increasingly stringent environmental regulations. Regular maintenance and monitoring are essential to ensure that these systems operate at peak efficiency. This includes checking for leaks, calibrating pressure controls, and ensuring that feed water quality meets required standards.

Once produced, steam travels through a network of pipes to reach its destination, where it is utilized for various applications. For instance, in a manufacturing facility, steam can drive turbines for electricity generation or be used in heating processes such as drying, sterilization, and pasteurization. The properties of steam, including its ability to carry large amounts of heat and its high temperature, make it an effective medium for energy transfer.

industrial steam system

However, the journey of steam does not end once it reaches its point of use. It is essential to implement effective steam management strategies to optimize usage and minimize losses. This includes insulating steam pipes to reduce heat loss, utilizing condensate return systems to recycle water back to the boiler, and employing steam traps to eliminate condensate without letting steam escape. Such practices not only improve efficiency but also contribute to substantial water and energy savings.

Additionally, steam systems must be carefully designed to meet the specific requirements of different applications. For example, processes that require continuous steam supply may necessitate a different boiler configuration compared to those needing batch operation. The integration of advanced control systems can facilitate real-time monitoring and adjustments, ensuring that steam output precisely matches demand. This adaptability is essential in industries where production loads can fluctuate significantly.

Moreover, the adoption of innovative technologies, such as cogeneration (combined heat and power), can further enhance the efficiency of industrial steam systems. By capturing and utilizing the waste heat from steam generation, businesses can significantly reduce their overall energy consumption and operational costs.

In conclusion, industrial steam systems are indispensable assets for a wide array of industries. Their efficient operation requires a comprehensive understanding of boiler efficiency, steam distribution, and management practices. By focusing on optimization and integrating advanced technologies, companies can improve their productivity while also contributing to environmental sustainability. As industries continue to evolve, the importance of steam systems in driving efficiency and innovation will remain paramount.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS