Jan . 26, 2025 01:02 Back to list

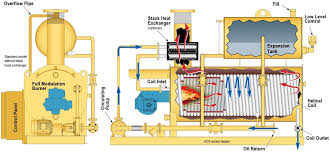

Gas (oil) fired steam boiler

When selecting the most efficient gas steam boiler for your needs, understanding key factors like efficiency ratings, reliability, and operational costs is imperative. Gas steam boilers are integral components in domestic heating systems, commercial buildings, and industrial processes due to their ability to provide consistent and high-quality steam. Thus, having substantial knowledge about these systems can aid in making informed decisions.

The trustworthiness of the product is significantly enhanced through quality assurance certificates and compliance with international performance standards. Modern gas steam boilers should adhere to standards set by organizations such as the American Society of Mechanical Engineers (ASME) or the Energy Star program. Such certifications ensure that the boiler meets stringent safety and efficiency criteria, offering consumers peace of mind regarding the product’s operational quality and environmental impact. A crucial aspect of real-world experience with gas steam boilers comes from post-installation considerations, including maintenance and lifecycle costs. Regular maintenance, including periodic inspections, cleaning, and timely replacement of worn parts, plays a vital role in maintaining the efficiency and longevity of the boiler. Establishing a consistent maintenance routine can prevent unexpected breakdowns and optimize the system’s performance throughout its lifespan. Energy savings, reduced emissions, and government incentives often accompany the choice of an efficient boiler. Many regions offer tax rebates or financial incentives for upgrading to high-efficiency models, reducing the upfront investment and speeding up return on investment. Furthermore, environmentally-conscious consumers are often relieved to find that efficient boilers contribute to reduced carbon footprints, aligning their choice with eco-friendly goals. In conclusion, selecting the most efficient gas steam boiler involves a comprehensive assessment of efficiency ratings, appropriate sizing, reputable manufacturing, adherence to standards, and maintenance regimes. By combining real-world experience with technical expertise and authoritative resources, consumers and businesses can invest in a solution that provides sustainable performance and significant energy savings. In a constantly evolving market, ongoing advancements and innovations continue to redefine the landscape, ensuring even greater efficiency and reliability for future heating applications.

The trustworthiness of the product is significantly enhanced through quality assurance certificates and compliance with international performance standards. Modern gas steam boilers should adhere to standards set by organizations such as the American Society of Mechanical Engineers (ASME) or the Energy Star program. Such certifications ensure that the boiler meets stringent safety and efficiency criteria, offering consumers peace of mind regarding the product’s operational quality and environmental impact. A crucial aspect of real-world experience with gas steam boilers comes from post-installation considerations, including maintenance and lifecycle costs. Regular maintenance, including periodic inspections, cleaning, and timely replacement of worn parts, plays a vital role in maintaining the efficiency and longevity of the boiler. Establishing a consistent maintenance routine can prevent unexpected breakdowns and optimize the system’s performance throughout its lifespan. Energy savings, reduced emissions, and government incentives often accompany the choice of an efficient boiler. Many regions offer tax rebates or financial incentives for upgrading to high-efficiency models, reducing the upfront investment and speeding up return on investment. Furthermore, environmentally-conscious consumers are often relieved to find that efficient boilers contribute to reduced carbon footprints, aligning their choice with eco-friendly goals. In conclusion, selecting the most efficient gas steam boiler involves a comprehensive assessment of efficiency ratings, appropriate sizing, reputable manufacturing, adherence to standards, and maintenance regimes. By combining real-world experience with technical expertise and authoritative resources, consumers and businesses can invest in a solution that provides sustainable performance and significant energy savings. In a constantly evolving market, ongoing advancements and innovations continue to redefine the landscape, ensuring even greater efficiency and reliability for future heating applications.

Share

Latest News

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS

Copyright © 2025 HEBEI HONGZE BOILER MANUFACTURING CO., LTD. All Rights Reserved. Sitemap | Privacy Policy