Nov . 09, 2024 20:16 Back to list

Understanding the Components of a Steam Boiler Schematic Diagram for Efficient Operation

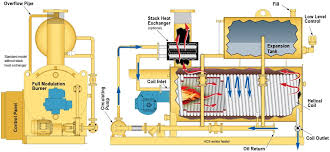

Understanding the Schematic Diagram of a Steam Boiler

A steam boiler is an essential piece of equipment used in various industries for generating steam through the heating of water. It plays a critical role in energy production, heating systems, and even some manufacturing processes. Understanding the schematic diagram of a steam boiler is fundamental for technicians, engineers, and anyone involved in the operation or maintenance of these systems. This article will break down the key components and their functions as illustrated in a typical steam boiler schematic.

What is a Schematic Diagram?

A schematic diagram is a visual representation that outlines the various parts of a system and shows how they connect and interact. This is especially significant in complex systems such as steam boilers, where numerous components must function seamlessly together to ensure efficiency and safety. The diagram typically includes symbols that represent different functionalities, making it easier to understand how the steam boiler operates.

Key Components of a Steam Boiler

1. Boiler Shell This is the outer casing of the steam boiler, providing structural integrity and containing the water and steam. It is usually made of high-quality steel to withstand high pressures.

2. Furnace Located at the bottom of the boiler, the furnace is where the fuel is burned to generate heat. The type of fuel used can vary, including natural gas, oil, or coal, depending on the design of the boiler.

3. Water Feed System This is responsible for supplying water to the boiler. The schematic diagram often shows a water feed pump, which moves water from a source, such as a tank, into the boiler.

4. Steam Drum As water is heated and converted to steam, it rises to the steam drum, where it collects. The steam drum is a crucial part of the boiler's operation, ensuring the separation of steam and water.

5. Steam Outlet This is the exit point for steam, allowing it to move into the piping system for use in heating or power generation. The outlet is often fitted with a safety valve to prevent over-pressure conditions.

schematic diagram of steam boiler

6. Blowdown Valve To maintain water quality and remove impurities, boilers use a blowdown process. The blowdown valve allows for the removal of concentrated water from the bottom of the boiler.

7. Safety Valves Safety is paramount in boiler operation. Safety valves are designed to release excess pressure automatically, preventing catastrophic failures.

8. Control Panel The control panel is where operators can monitor and adjust the boiler's performance. It typically includes gauges that display temperature, pressure, and water levels, along with controls for automation.

Types of Steam Boilers

There are different types of steam boilers, and each has its unique schematic diagram reflecting its design and function. The most common types include

- Fire-Tube Boilers In these systems, hot gases from the furnace pass through tubes submerged in water, heating it to produce steam. The schematic for a fire-tube boiler typically shows these tubes surrounded by water.

- Water-Tube Boilers Here, water flows through tubes heated by hot gases. This design allows for higher pressures and is used in large-scale applications. The schematic would illustrate the number of water tubes and their arrangement.

- Electric Boilers Instead of burning fuel, these boilers use electricity to heat water. The schematic for an electric boiler highlights the heating elements and electrical connections.

Conclusion

Understanding the schematic diagram of a steam boiler is crucial for anyone involved in its operation, maintenance, or design. Each component plays a vital role in ensuring the boiler operates safely and efficiently. Familiarity with these schematics not only aids in troubleshooting and maintenance but also enhances overall operational performance. As industries continue to evolve and seek more efficient energy solutions, the steam boiler remains a cornerstone technology, adapting to new challenges while remaining true to its fundamental purpose generating steam for energy and heat. Whether for residential use or large industrial applications, the steam boiler continues to be an indispensable tool in our everyday lives.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS