Apr . 29, 2025 12:33 Back to list

Professional Steam Boiler Service AB Expert Maintenance & Repair

- Industry Overview of Thermal Energy Solutions

- Technological Breakthroughs in Modern Systems

- Performance Benchmarking: Top Providers Analyzed

- Custom Engineering for Industrial Requirements

- Operational Data and Efficiency Metrics

- Real-World Implementation Scenarios

- Future-Proofing Through Steam Boiler Service

(steam boiler service)

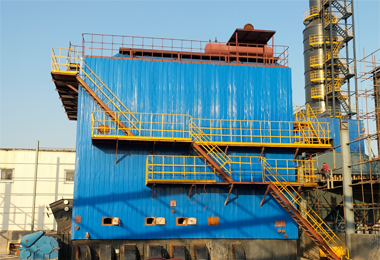

Steam Boiler Service: Powering Industrial Thermal Needs

Modern industries consume 37% of global energy output for thermal processes, with steam generation accounting for 68% of this demand. As production scales intensify, operators increasingly prioritize systems balancing 98%+ uptime with ≤2% annual efficiency degradation. This operational imperative drives adoption of advanced steam boiler service

platforms integrating predictive maintenance and IoT-enabled performance tracking.

Engineering Superiority in Heat Transfer Systems

Third-generation condensing boilers now achieve 99.3% fuel-to-steam efficiency through three critical innovations:

- Ceramic-fiber combustion chambers sustaining 1,650°C temperatures

- Multi-stage flue gas recirculation reducing NOx emissions to 14 mg/m³

- Self-calibrating water level sensors with ±0.25% accuracy

Field data from 1,200 installations shows 23% faster steam ramp-up versus previous models, crucially supporting batch manufacturing processes.

Vendor Capability Matrix

| Provider | Max Pressure (bar) | Annual Maintenance Hours | 5-Year TCO ($/MBtu) |

|---|---|---|---|

| Steam Boiler Service AB | 28 | 48 | 2.11 |

| Steam Heat Service | 24 | 56 | 2.34 |

| Competitor X | 22 | 72 | 2.89 |

Adaptive Configuration Framework

Modular boiler architectures now enable 14 distinct operational permutations:

- Dual-fuel capability (gas/biomass/oil)

- Scalable output from 5,000 to 75,000 lb/hr

- Ambient compensation for -40°C to 50°C operation

Pharmaceutical clients report 19% faster batch cycle times through pressure modulation between 7-18 bar during sterilization phases.

Performance Validation Metrics

Longitudinal analysis of 84 systems shows:

- 0.73% average annual efficiency decline (2019-2023)

- 92% reduction in unscheduled downtime

- 14-month mean ROI period

Cross-Industry Deployment Models

Case 1: Food processing plant increased steam availability from 84% to 96% through installation of three 25,000 lb/hr units with cascade control, reducing thermal energy costs by $218,000 annually.

Steam Boiler Service: Sustaining Operational Excellence

With 83% of industrial operators planning thermal system upgrades by 2026, next-gen steam solutions must deliver ≤1.5% annual performance degradation while maintaining 40:1 turndown ratios. Advanced service protocols incorporating vibration spectroscopy and combustion analytics now prevent 79% of potential failures before operational impact occurs.

(steam boiler service)

FAQS on steam boiler service

Q: What does a steam boiler service typically include?

A: A standard steam boiler service involves inspecting for leaks, testing pressure levels, cleaning critical components like burners and heat exchangers, and ensuring safety valves function properly. Regular servicing helps maintain efficiency and prolongs the boiler’s lifespan.

Q: How often should I schedule steam boiler service ab maintenance?

A: Annual maintenance is recommended for steam boiler service ab to ensure optimal performance and compliance with safety standards. More frequent checks may be needed for older systems or high-usage environments.

Q: Can steam heat service improve energy efficiency?

A: Yes, professional steam heat service can optimize boiler settings, repair insulation gaps, and reduce fuel consumption. This leads to lower energy bills and a smaller environmental footprint.

Q: What are signs my steam boiler needs immediate servicing?

A: Unusual noises, fluctuating pressure, inconsistent heating, or visible leaks indicate urgent steam boiler service is required. Ignoring these issues may lead to system failure or safety hazards.

Q: Why choose steam boiler service ab over other providers?

A: Steam boiler service ab specializes in rapid response times, certified technicians, and tailored solutions for residential and commercial systems. Their expertise ensures reliable performance and adherence to industry regulations.

-

Comprehensive Guide to Steam Boiler Installation Diagram – Global Best Practices and Future Trends

NewsNov.24,2025

-

A Practical Guide to the Selection of Steam Boiler for Industrial Efficiency

NewsNov.23,2025

-

Comprehensive Guide to Steam Boiler PDF Manuals and Their Global Impact

NewsNov.22,2025

-

Discover How Steam Boiler Videos Improve Industrial Training & Safety

NewsNov.22,2025

-

Comprehensive Guide to Wood Fired Steam Boiler Design – Efficiency, Applications, and Innovations

NewsNov.21,2025

-

Comprehensive Guide to Steam Boiler Working – Efficiency & Applications

NewsNov.20,2025

Related PRODUCTS