Nov . 19, 2024 10:42 Back to list

Optimizing Condensate Return Pump Systems for Efficient Steam Boiler Operations

Steam Boiler Condensate Return Pump An Overview

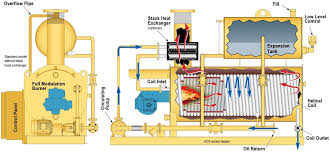

In the industrial sector, steam boilers play a crucial role in a wide array of applications, from heating to power generation. One essential component of steam boiler systems is the condensate return pump, which is pivotal for maintaining efficiency in the operation of steam systems. This article delves into the function, importance, and operation of condensate return pumps in steam boiler systems.

What is a Condensate Return Pump?

A condensate return pump is designed to collect and return the condensate – the water formed when steam cools and condenses – back to the boiler for reuse. This process is critical for steam systems, as it minimizes water waste and enhances overall efficiency. By recycling condensate, facility operators can significantly reduce water treatment costs, conserve energy, and lower overall operating expenses.

Importance of Condensate Return Pumps

The importance of condensate return pumps in steam boiler operations cannot be overstated. Here are several key reasons

1. Efficiency Improvement By returning condensate to the boiler, these pumps help maintain the water level needed for optimal steam generation. This prevents the boiler from running dry, which could lead to costly damages and downtime.

2. Cost Saving Water is a valuable resource. By reusing condensate, facilities can lower their water treatment costs and reduce the consumption of fresh water. This is particularly beneficial in industries where water is a significant operational cost.

steam boiler condensate return pump

3. Temperature Control Condensate return pumps help stabilize the temperature in steam systems. This is essential because fluctuations in temperature can lead to inefficiencies and increased wear on equipment.

4. Reduction of Energy Consumption By recycling steam, less energy is required to heat new water to generate steam, leading to lower fuel costs. This contributes to a more environmentally friendly operation, as less fuel consumption correlates with decreased greenhouse gas emissions.

How Do Condensate Return Pumps Work?

Typically, condensate return pumps operate using a float switch or other level-sensing devices to monitor the water level in the condensate collection tank. When the level reaches a certain point, the pump activates and conveys the condensate back to the boiler. These pumps can be either centrifugal or positive displacement types, with each type having its distinct advantages based on system requirements.

Maintenance is vital to ensure the reliability of condensate return pumps. Regular inspections and servicing can prevent issues such as blockages, wear on moving parts, and other mechanical failures that could lead to interruptions in steam supply.

Conclusion

In summary, steam boiler condensate return pumps are integral components of industrial steam systems, facilitating efficiency and cost savings. By ensuring that condensate is effectively returned to the boiler, these pumps play a crucial role in the sustainable operation of steam systems. As industries continue to seek ways to improve efficiency and reduce costs, understanding the significance and operation of condensate return pumps will remain essential.

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

-

High Efficiency Coal Fired Hot Water Boiler for Reliable Heating

NewsJul.28,2025

-

High Efficiency Coal Fired Thermal Oil Boiler for Industrial Heating

NewsJul.26,2025

Related PRODUCTS