Oct . 18, 2024 06:06 Back to list

Understanding and Improving Efficiency in Steam Boiler Operations and Performance

Understanding Steam Boiler Efficiency Key Factors and Optimizations

Steam boilers play a critical role in various industries, from power generation to food processing. Their primary function is to generate steam by heating water, which is then used to power turbines, heat buildings, or provide heat in industrial processes. However, the efficiency of steam boilers can vary significantly, affecting operational costs and environmental impact. This article delves into the concept of steam boiler efficiency, key influencing factors, and strategies for optimization.

What is Steam Boiler Efficiency?

Steam boiler efficiency refers to the ratio of useful energy output to the energy input, expressed as a percentage. In simpler terms, it measures how well a boiler converts fuel into usable steam. A boiler operating at high efficiency will produce a greater amount of steam from a given amount of fuel compared to a less efficient boiler, resulting in lower fuel costs and reduced emissions.

Efficiency is typically defined through two main metrics thermal efficiency and combustion efficiency. Thermal efficiency considers the heat transfer process, while combustion efficiency assesses how effectively the fuel is converted to energy. Ideal boiler efficiency is usually above 80%, with modern systems reaching upwards of 90%.

Factors Influencing Boiler Efficiency

1. Design and Configuration The design of a boiler greatly impacts its efficiency. For instance, fire-tube boilers generally have higher efficiency compared to water-tube boilers in smaller applications. Additionally, advanced designs, such as condensing boilers, can recover heat from exhaust gases, thus increasing overall efficiency.

2. Fuel Type The type of fuel used in the boiler significantly affects efficiency. Different fuels have varying energy contents and combustion characteristics. Natural gas typically offers higher efficiency levels compared to coal or oil, and it produces fewer emissions. Furthermore, the moisture content in the fuel can also dilute the energy produced, negatively impacting efficiency.

3. Water Quality The quality of water used in steam boilers can affect scaling and corrosion, which, in turn, impacts efficiency. Hard water can lead to scale buildup on heat transfer surfaces, reducing the boiler’s ability to transfer heat. Regular treatment and monitoring of water quality are essential to maintain high efficiency.

4. Operating Practices Operators play a pivotal role in maintaining efficiency. Regular maintenance, including cleaning, calibration, and inspection, ensures that boilers operate at peak performance. Additionally, the way the boiler is operated—such as maintaining appropriate pressure and temperature settings—can optimize efficiency.

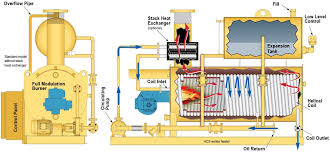

steam boiler efficiency

5. Control Systems Modern steam boilers often incorporate advanced control systems that dynamically adjust operations based on real-time data. These systems optimize fuel-to-steam ratios and minimize waste, ensuring that the boiler runs at the most efficient setting for the current load.

Optimizing Steam Boiler Efficiency

Achieving high steam boiler efficiency hinges on a combination of best practices, regular maintenance, and technology implementation. Here are some strategies to consider

1. Regular Maintenance and Inspections Regular maintenance schedules should include cleaning the heat exchanger surfaces, checking for leaks, and ensuring safe operation. This prevents inefficiencies caused by malfunctions or build-up from dust and impurities.

2. Heat Recovery Systems Implementing economizers can recover heat from flue gases to preheat incoming feedwater, significantly reducing energy consumption. This can improve overall boiler efficiency by reducing the amount of fuel needed to achieve the desired steam output.

3. Upgrading Components When considering upgrades, focus on modern burners and control systems that can provide more precise fuel and air ratios. Intelligent controls can adapt to changing demands and boiler loads, improving efficiency.

4. Training for Operators Proper training for operators ensures they understand the boiler systems, maintenance needs, and operational best practices. A knowledgeable workforce can quickly identify inefficiencies and take corrective actions.

5. Monitoring Performance Implementing continuous monitoring systems can help track boiler performance. Regularly analyzing data allows for proactive adjustments and highlights areas for improvement.

Conclusion

Optimizing steam boiler efficiency is crucial for reducing operational costs and minimizing environmental impact. By understanding the various factors that influence efficiency and implementing effective strategies, industries can enhance their boiler performance, ensuring sustainable and economically viable operations. As technology continues to advance, opportunities for improving boiler efficiency will likely expand, leading to more energy-efficient processes across sectors.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS