Nov . 29, 2024 12:56 Back to list

Essential Safety Features for Steam Boilers in Industrial Applications

Steam Boiler Safety Devices Ensuring Operational Safety

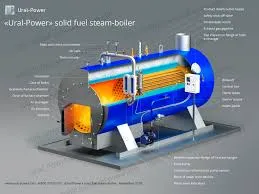

Steam boilers are critical components in many industrial processes, providing the steam necessary for heating, power generation, and mechanical processes. However, the high pressures and temperatures involved in steam generation pose significant safety risks. To mitigate these risks, various safety devices are integrated into the design and operation of steam boilers. This article explores the essential safety devices that ensure the safe operation of steam boilers, enhancing both efficiency and safety.

1. Pressure Relief Valves

One of the most vital safety devices in a steam boiler is the pressure relief valve. These valves are designed to automatically release steam when the pressure inside the boiler exceeds a predetermined limit. This overpressure scenario could lead to boiler failure or even explosion if not addressed promptly. The pressure relief valve is typically calibrated to open at a specific pressure and close once the pressure returns to normal levels. Regular maintenance and testing of these valves are crucial to ensure their proper functioning.

2. Water Level Controls

Maintaining the proper water level within the boiler is critical for safe operation. Too little water can cause the boiler to overheat, potentially leading to severe damage, while too much water can result in carryover, where water contaminates the steam supply. Water level controls include low water cut-off devices and water level gauges. The low water cut-off device shuts down the boiler automatically if the water level falls below a safe threshold, thereby preventing overheating. Water level gauges provide operators with a visual indication of the water level, helping them make informed decisions.

Safety shutoff valves serve as an additional layer of protection by isolating the boiler from the fuel supply in the event of a malfunction. These valves operate automatically or manually and are crucial in preventing leaks or explosions. When a safety shutoff valve is activated, it cuts off the fuel supply to the burner, preventing further ignition and potential hazards. Regular testing of these valves is essential to verify that they function correctly when needed.

steam boiler safety devices

4. Blow-off Valves

Blow-off valves are important for maintaining water quality within the boiler. Over time, impurities and contaminants can accumulate, which can lead to scaling and corrosion. Blow-off valves allow operators to periodically release small amounts of water from the boiler, along with the accumulated sludge and impurities. This process helps maintain the efficiency and longevity of the boiler system. Operators should establish a routine blow-down schedule to keep water quality in check.

5. Burner Management Systems

Modern steam boilers often come equipped with sophisticated burner management systems that monitor and control the combustion process. These systems ensure safe ignition, stable operation, and automatic shutdown in case of unsafe conditions (e.g., flame failure, excessive emissions). Through continuous monitoring and automated responses, these systems reduce the risk of hazardous situations, such as uncontrolled combustion or explosions.

6. Emergency Shutdown Systems

In addition to component-specific safety devices, emergency shutdown systems are critical for the overall safety of steam boilers. These systems are designed to shut down the entire boiler operation during critical failures or emergencies. They often involve multiple interlocks and safety mechanisms to ensure that all fuel sources are terminated, and the boiler is brought to a safe state.

Conclusion

The safety devices integrated into steam boilers play a crucial role in ensuring that these powerful machines operate safely and efficiently. Regular maintenance, testing, and compliance with safety regulations are essential to ensure that these devices function correctly, thus preventing accidents and enhancing the reliability of boiler operations. As industries continue to rely on steam boilers for various applications, advancements in safety technology will further enhance the safety landscape, ensuring that the risks associated with steam generation are managed effectively.

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS