Feb . 05, 2025 01:15 Back to list

steam boiler troubleshooting guide

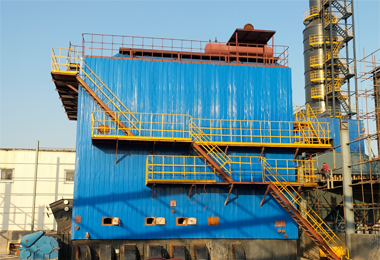

Effective troubleshooting of steam boilers is crucial for maintaining their efficiency, safety, and longevity. Steam boilers, often the heart of industrial operations and building HVAC systems, can develop issues requiring prompt and informed solutions. Understanding common problems and applying expertise in diagnosing and resolving these issues can save time, reduce costs, and ensure continuous operation.

Burner malfunction is another prevalent issue affecting steam boilers, often manifesting as uneven combustion or failure to ignite. This problem can have roots in several components, including faulty ignitors, improper fuel-to-air ratios, or dirty burner nozzles. Routine maintenance should include inspection and cleaning of burner components, adjustment of fuel-to-air ratios, and verification of proper combustion settings. Expert knowledge in combustion systems is indispensable for diagnosing such issues and ensuring optimal performance. Corrosion is a potentially severe problem that can lead to leaks and structural weaknesses within a boiler system. It often occurs when there's an electrochemical reaction between metal surfaces and dissolved oxygen in the water. Preventive strategies include implementing deaeration systems to remove oxygen from feedwater and applying chemical oxygen scavengers as part of a comprehensive water treatment regime. Professionals specializing in corrosion control can evaluate existing mitigation strategies and introduce innovative solutions that enhance the life cycle of boilers. Noise issues, such as banging or knocking in the pipes, are typically indicative of steam trapping problems or water hammer. Such occurrences can cause damage to the piping system and demand immediate attention. This issue requires skillful analysis to determine whether traps are correctly operating or if there are condensate management failures. Technicians with experience in steam dynamics can provide invaluable insights and solutions that address the root causes of these auditory symptoms. In sum, mastering the troubleshooting of steam boilers demands a combination of experience, expertise, and a thorough understanding of the components involved. Those tasked with maintenance and problem-solving should be adept in employing diagnostic tools and methodologies consistent with industrial standards. These skills not only ensure operational efficiency and safety but also affirm trust and reliability in industrial operations. A well-maintained boiler system stands as a testament to the efficacy of advanced troubleshooting capabilities, contributing to the broader goal of sustainable and efficient energy use.

Burner malfunction is another prevalent issue affecting steam boilers, often manifesting as uneven combustion or failure to ignite. This problem can have roots in several components, including faulty ignitors, improper fuel-to-air ratios, or dirty burner nozzles. Routine maintenance should include inspection and cleaning of burner components, adjustment of fuel-to-air ratios, and verification of proper combustion settings. Expert knowledge in combustion systems is indispensable for diagnosing such issues and ensuring optimal performance. Corrosion is a potentially severe problem that can lead to leaks and structural weaknesses within a boiler system. It often occurs when there's an electrochemical reaction between metal surfaces and dissolved oxygen in the water. Preventive strategies include implementing deaeration systems to remove oxygen from feedwater and applying chemical oxygen scavengers as part of a comprehensive water treatment regime. Professionals specializing in corrosion control can evaluate existing mitigation strategies and introduce innovative solutions that enhance the life cycle of boilers. Noise issues, such as banging or knocking in the pipes, are typically indicative of steam trapping problems or water hammer. Such occurrences can cause damage to the piping system and demand immediate attention. This issue requires skillful analysis to determine whether traps are correctly operating or if there are condensate management failures. Technicians with experience in steam dynamics can provide invaluable insights and solutions that address the root causes of these auditory symptoms. In sum, mastering the troubleshooting of steam boilers demands a combination of experience, expertise, and a thorough understanding of the components involved. Those tasked with maintenance and problem-solving should be adept in employing diagnostic tools and methodologies consistent with industrial standards. These skills not only ensure operational efficiency and safety but also affirm trust and reliability in industrial operations. A well-maintained boiler system stands as a testament to the efficacy of advanced troubleshooting capabilities, contributing to the broader goal of sustainable and efficient energy use.

Share

Latest News

-

High-Efficiency Commercial Oil Fired Steam Boiler for Industry

NewsJul.30,2025

-

High-Efficiency Biomass Fired Thermal Oil Boiler Solutions

NewsJul.30,2025

-

High Efficiency Gas Fired Thermal Oil Boiler for Industrial Heating

NewsJul.29,2025

-

High-Efficiency Gas Fired Hot Water Boiler for Sale – Reliable & Affordable

NewsJul.29,2025

-

High Efficiency Biomass Fired Hot Water Boiler for Industrial and Commercial Use

NewsJul.29,2025

-

High-Efficiency Biomass Fired Hot Water Boiler for Industrial Use

NewsJul.28,2025

Related PRODUCTS

Copyright © 2025 HEBEI HONGZE BOILER MANUFACTURING CO., LTD. All Rights Reserved. Sitemap | Privacy Policy